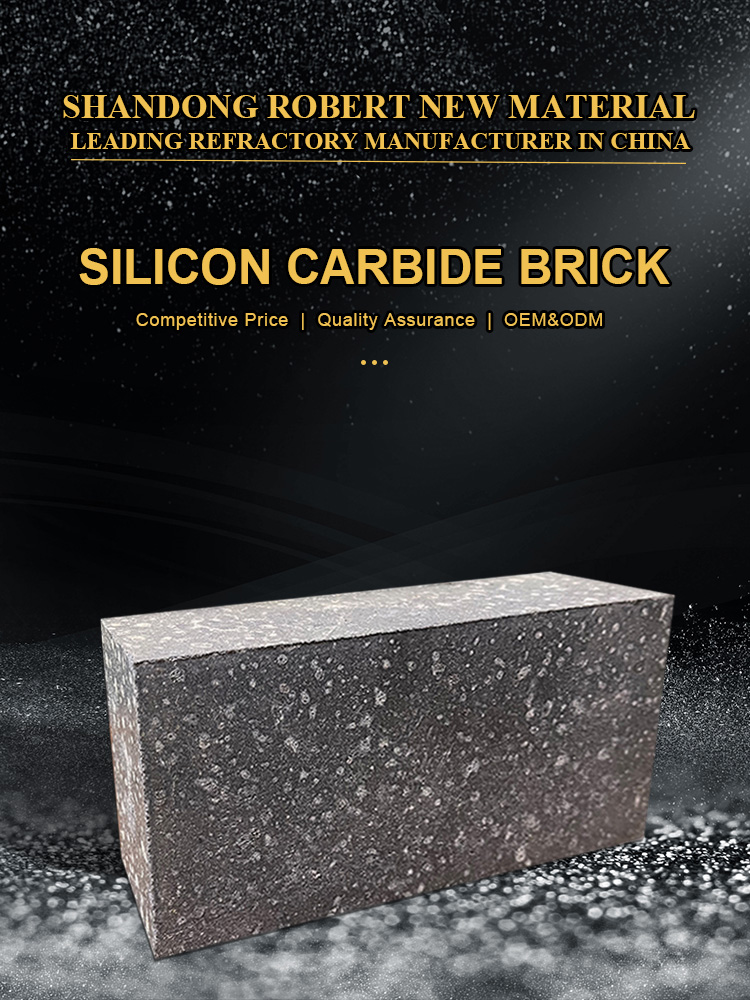

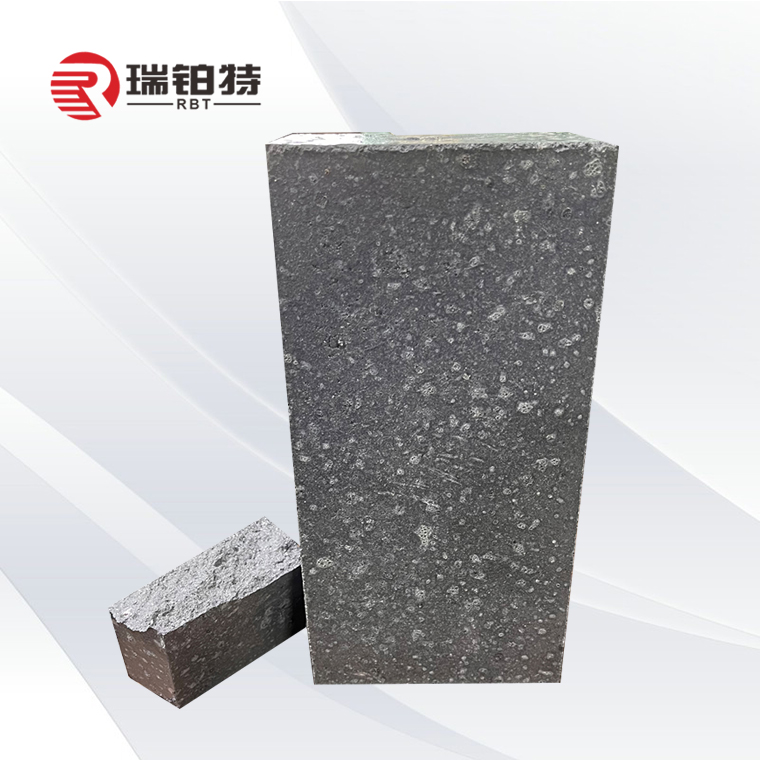

Silicon Carbide Zvidhinha

Product Information

| ProductZita | Silicon Carbide Zvidhinha |

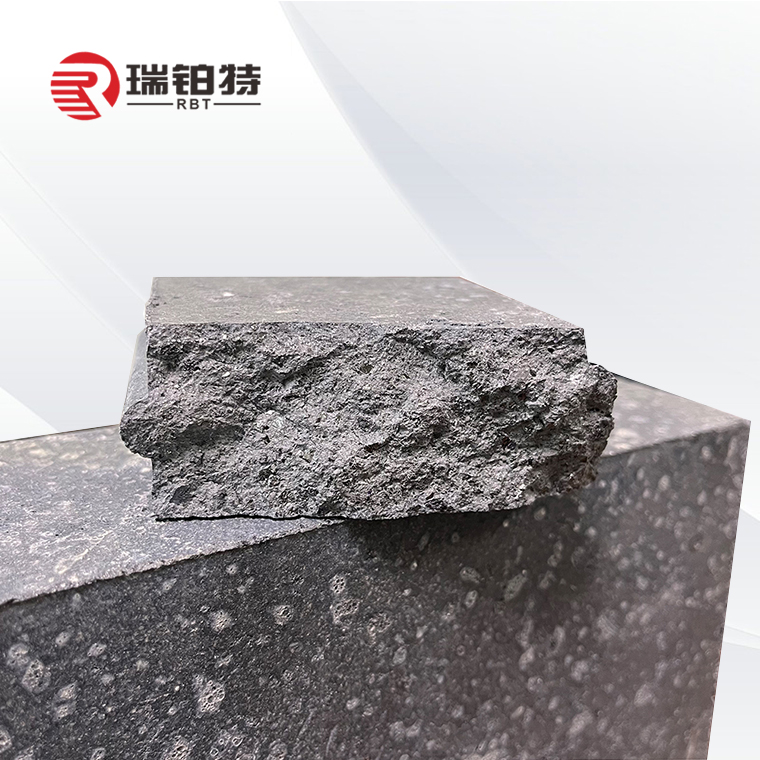

| Tsanangudzo | Silicon carbide zvidhinha zvakavakirwa pasilicon carbide sechinhu chikuru chemidziyo, okisidhi sebinder kupfurwa kwezvinhu zvinoramba. |

| Classification | Clay sintered, Si3N4 Sintered, Sialon sintered, β-SiC sintered, Si2ON2 sintered, Recrystallization |

| Size | Saizi yakajairika: 230 x 114 x 65 mm, saizi yakakosha uye sevhisi yeOEM inopawo! |

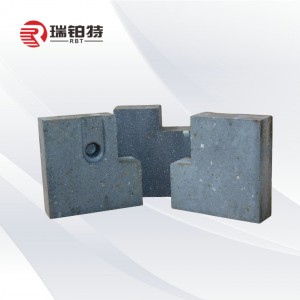

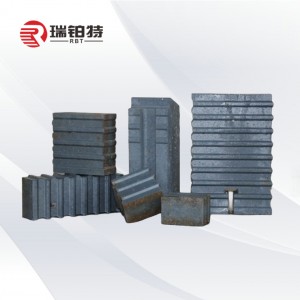

| Shape | Zvidhinha zvakananga, zvidhinha zvine chimiro chakasarudzika, zvinodiwa nevatengi! |

| Features | 1. Yakanakisa oxidation kuramba 2. Thermal shock stability 3. Compact structure 4. High tembiricha vhoriyamu kugadzikana 5. High tembiricha flexural simba |

Details Images

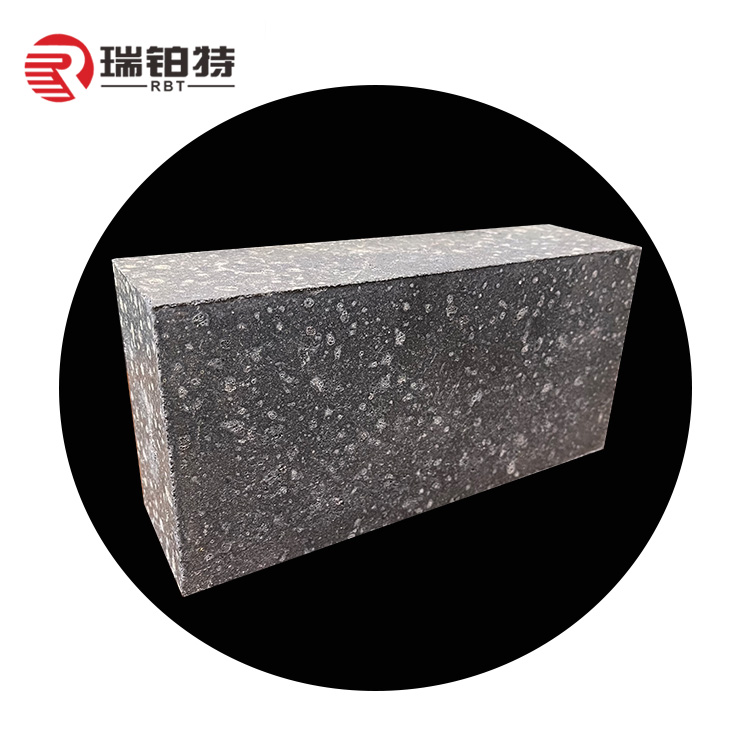

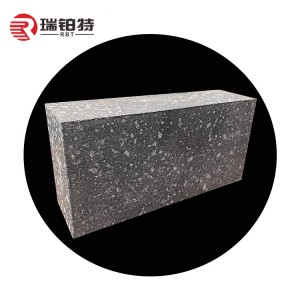

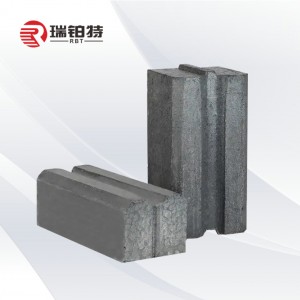

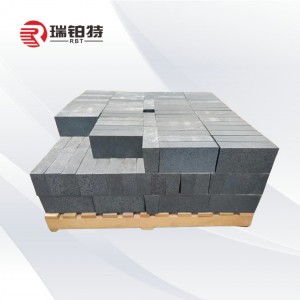

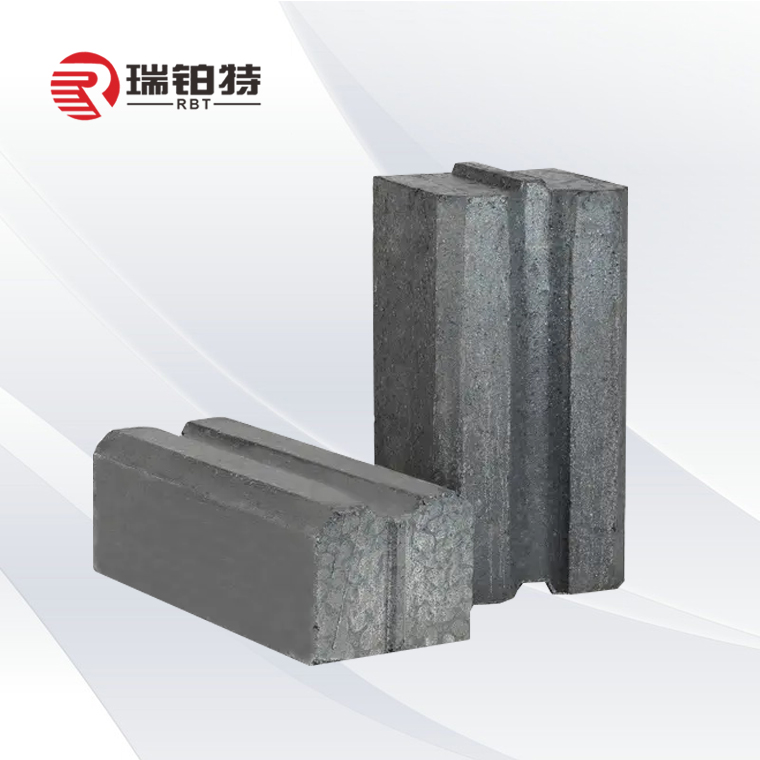

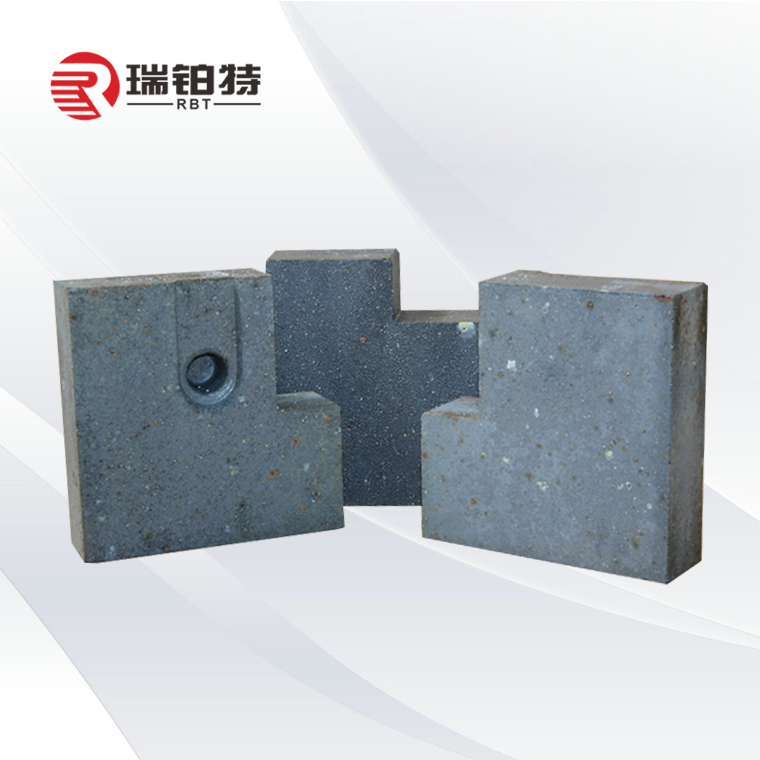

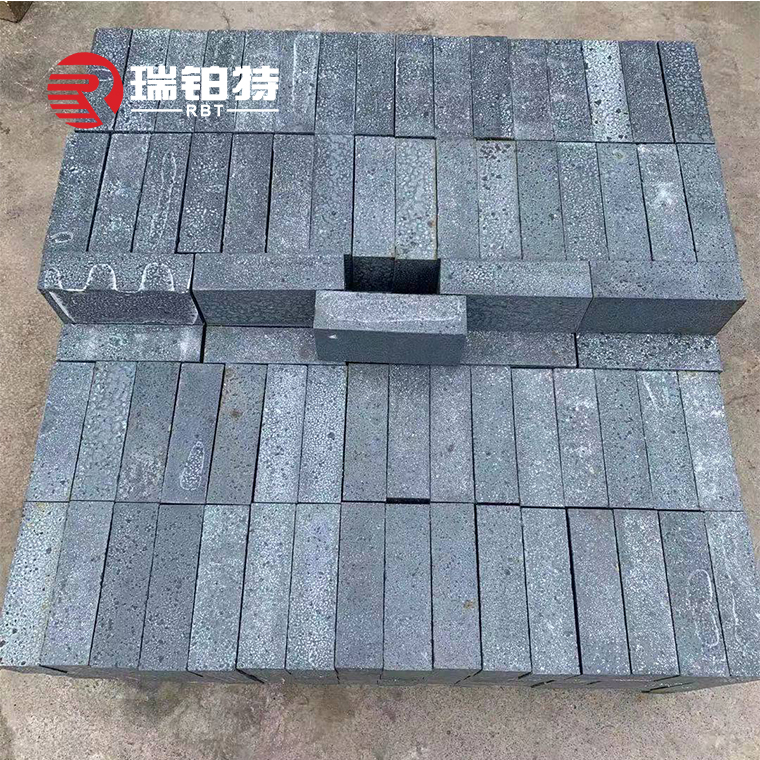

Standard Bricks

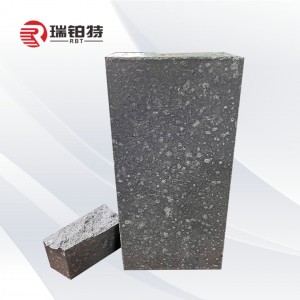

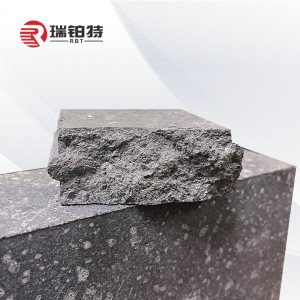

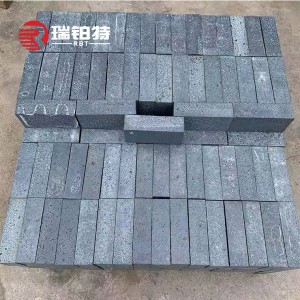

Zvidhinha Zvakaumbwa

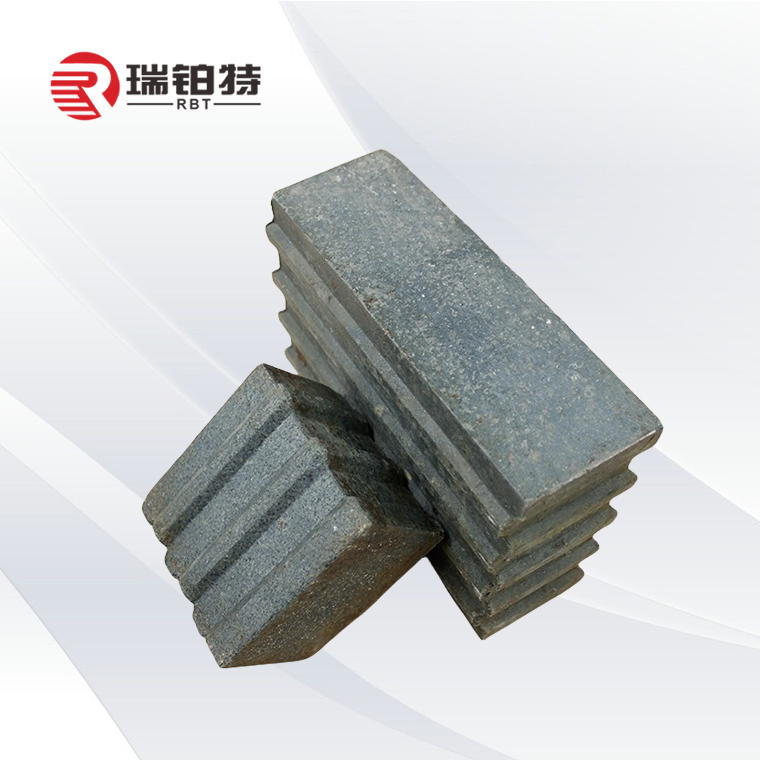

Zvidhinha Zvakaumbwa

Zvidhinha Zvakaumbwa

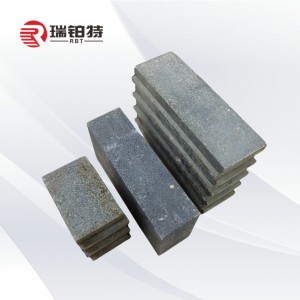

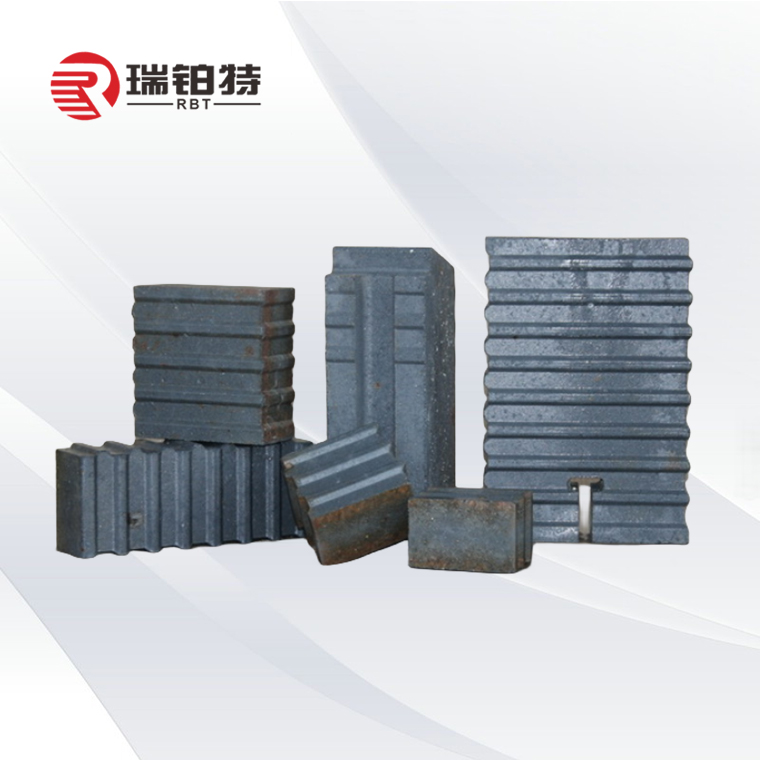

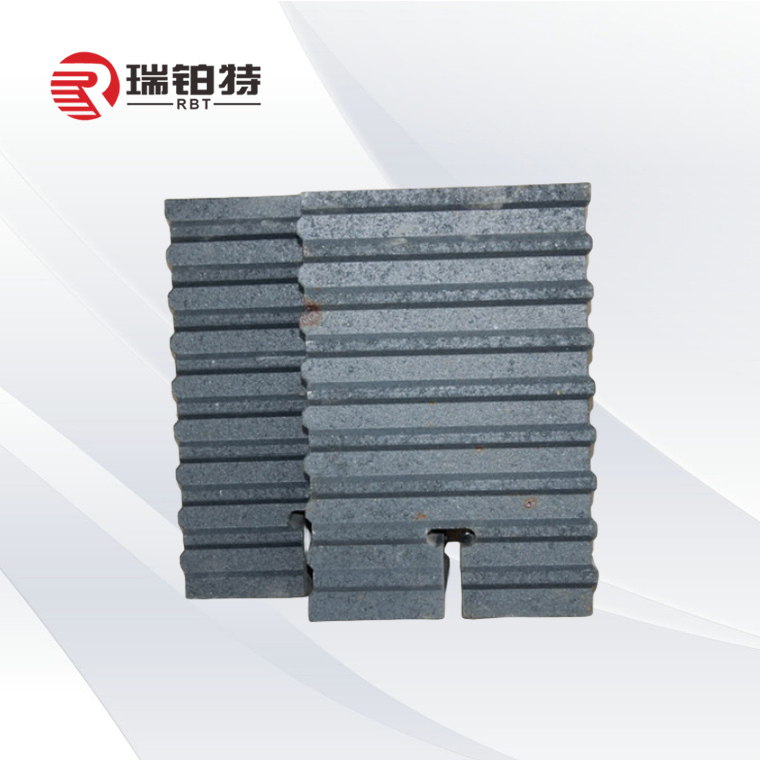

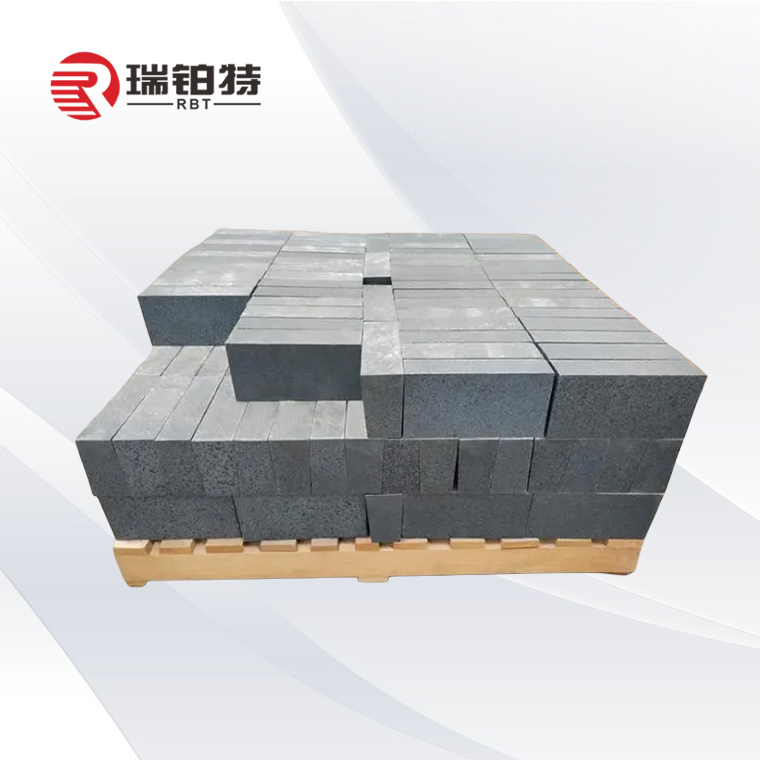

Standard Bricks

Zvidhinha Zvakaumbwa

Zvidhinha Zvakaumbwa

Zvidhinha Zvakaumbwa

Product Index

| INDEX | RBTSC |

| Refractoriness(℃) ≥ | 1750 |

| Bulk Density(g/cm3) ≥ | 2.60 |

| Inooneka Porosity(%) ≤ | 10 |

| Cold Crushing Strength(MPa) ≥ | 80 |

| Thermal conductivity (W/mk) | 8-15 |

| Refractoriness Under Load@ 0.2MPa(℃) ≥ | 1700 |

| SIC(%) ≥ | 85 |

| SiO2(%) ≥ | 10 |

Application

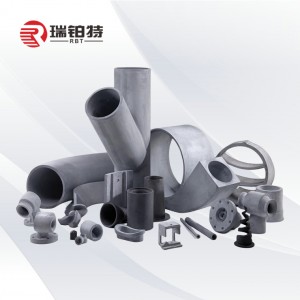

1. Inogona kushandiswa mune metallurgical steel drum linings, nozzles, plugs, blast furnace bottoms uye mabhosi, mvura-yakatonhorera slide rails mumoto unopisa;

2. Non-ferrous metal smelting stills, distillation tower trays, side wall of electrolyzers, smelting metal crucibles;

3. Masherufu eSilicic acid masherufu uye zvinhu zvisingapise moto zvehovhoni dzeindasitiri yemunyu;

4. Mafuta uye gasi majenareta uye organic tsvina yekupisa mavira muindasitiri yemakemikari;

5. Kilni fenicha yemhando yepamusoro yekeramics, aruminiyamu electrolytic cell linings, akanyungudutswa aruminiyamu conduits, uye muchoto fenicha yemabhini edongo, hombe nepakati-kati kuputika kwemoto kunopisa muviri wepasi, chiuno chechoto uye dumbu, aruminiyamu yekunatsa choto lining, zinc distillation tank lining. , nezvimwewo.

Blast Furnace

Rotary Kiln

Ceramic Kiln

Chemical Industry

Package&Warehouse

Mibvunzo Inowanzo bvunzwa

Kuda rubatsiro?Iva nechokwadi chekushanyira maforamu edu ekutsigira mhinduro kumibvunzo yako!

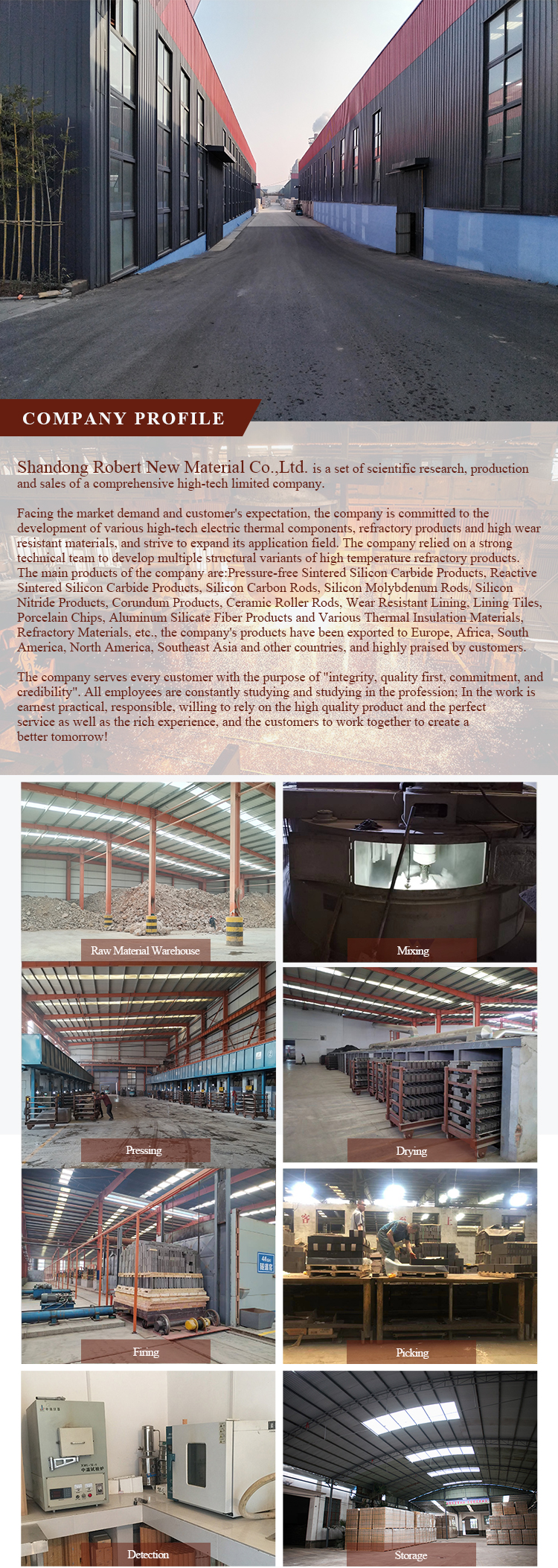

Isu tiri mugadziri chaiye, fekitori yedu inyanzvi mukugadzira zvinhu zvekuramba kweanopfuura makore makumi matatu.Isu tinovimbisa kupa mutengo wakanakisa, yakanakisa pre-kutengesa uye mushure mekutengesa sevhisi.

Kune yega yega maitiro ekugadzira, RBT ine yakazara QC sisitimu yemakemikari ekuumbwa uye emuviri zvivakwa.Uye isu tichaedza zvinhu, uye chitupa chemhando ichaendeswa nenhumbi.Kana iwe uine zvakakosha zvinodiwa, isu tichaedza nepatinogona napo kuti tivape pekugara.

Zvichienderana nehuwandu, nguva yedu yekuendesa yakasiyana.Asi isu tinovimbisa kutumira nekukurumidza sezvinobvira nemhando yakavimbiswa.

Zvechokwadi, tinopa sampuli dzemahara.

Hongu, hongu, unogamuchirwa kushanyira kambani yeRBT uye zvigadzirwa zvedu.

Iko hakuna muganho, isu tinogona kupa yakanakisa zano uye mhinduro zvinoenderana nemamiriro ako.

Tave tichigadzira zvinhu zvekuramba kweanopfuura makore makumi matatu, tine rutsigiro rwakasimba rwehunyanzvi uye ruzivo rwakapfuma, tinokwanisa kubatsira vatengi kugadzira kilns dzakasiyana uye kupa imwe-stop service.