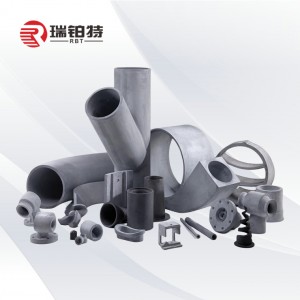

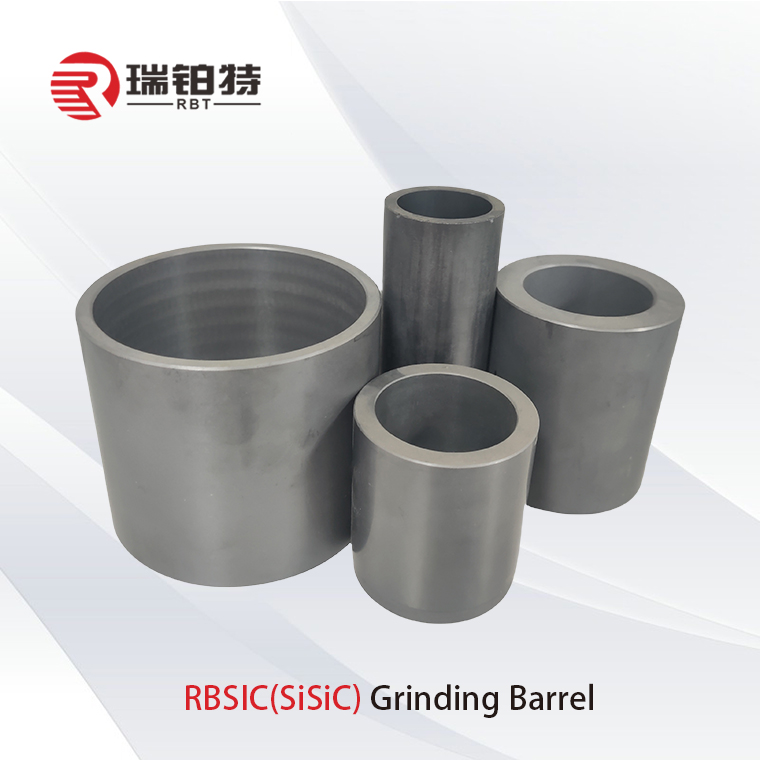

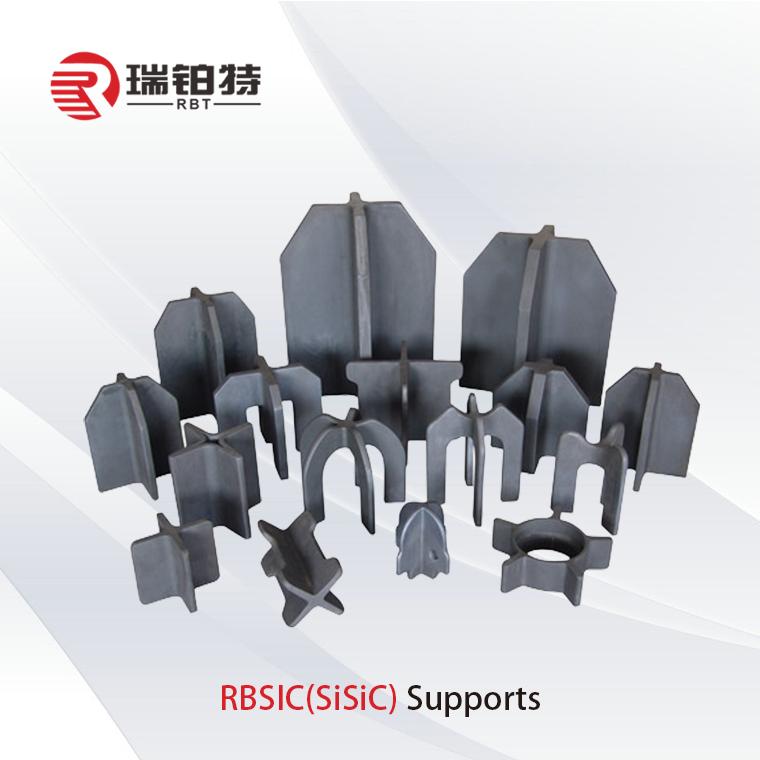

RBSiC(SiSiC) Zvigadzirwa

Product Information

| ProductZita | RBSIC(SiSiC) Zvigadzirwa(Reactive Sintering Silicon Carbide Zvigadzirwa) |

| Tsanangudzo | Siliconized SiC inonzi silicon reaction iyo inosanganiswa zvakafanana uye inopindwa neakatsetseka zvidimbu zveSiC, kabhoni poda uye ekuwedzera muchiyero kugadzira SiC uye kusanganisa neSiC, yakawandisa silicon inozadza mapeji kuti iwane yakanyanya kusimba zveceramic zvinhu. |

| Feature | Izvo zvinhu zvesiliconized silicon carbide zvine nhevedzano yehukuru hwepamusoro uye hunhu hwakadai sesimba rakakwirira, kuomarara kwakanyanya, kupfeka kuramba, kushivirira kwekushisa kwepamusoro, corrosion resistance, oxidation resistance thermal shock resistance, high thermal conductivity, low coefficient of thermal expansion, creep resistance under. kupisa kwakanyanya uye zvichingodaro. Zvigadzirwa zvakawanda zvinogona kugadzirwa kubva pazviri zvakaita sematanda, ma roller, pombi dzemhepo dzinotonhorera, machubhu ekudzivirira maviri, machubhu ekuyeresa tembiricha, zvikamu zvekuisa chisimbiso, uye zvikamu zvakaumbwa. |

Product Index

| Item | Unit | Data |

| Max Tembiricha Yekushandisa | ℃ | ≤1380 |

| Density | g/cm3 | >3.02 |

| Vhura Porosity | % | ≤0.1 |

| Bending Strength | Mpa | 250(20℃);280(1200℃) |

| Modulus yeElastictiy | Gpa | 330(20℃);300(1200℃) |

| Thermal Conductivity | W/mk | 45(1200℃) |

| Thermal Kuwedzera Coefficient | K-1*10-6 | 4.5 |

| Kuoma kwaMoh | | 9.15 |

| Acid Alkaline-Uchapupu | | Excellent |

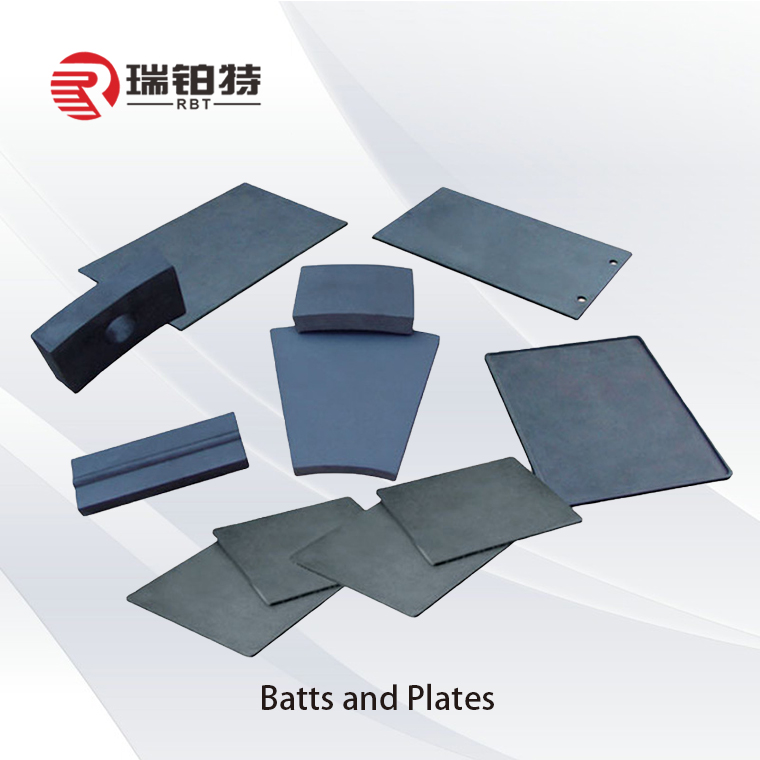

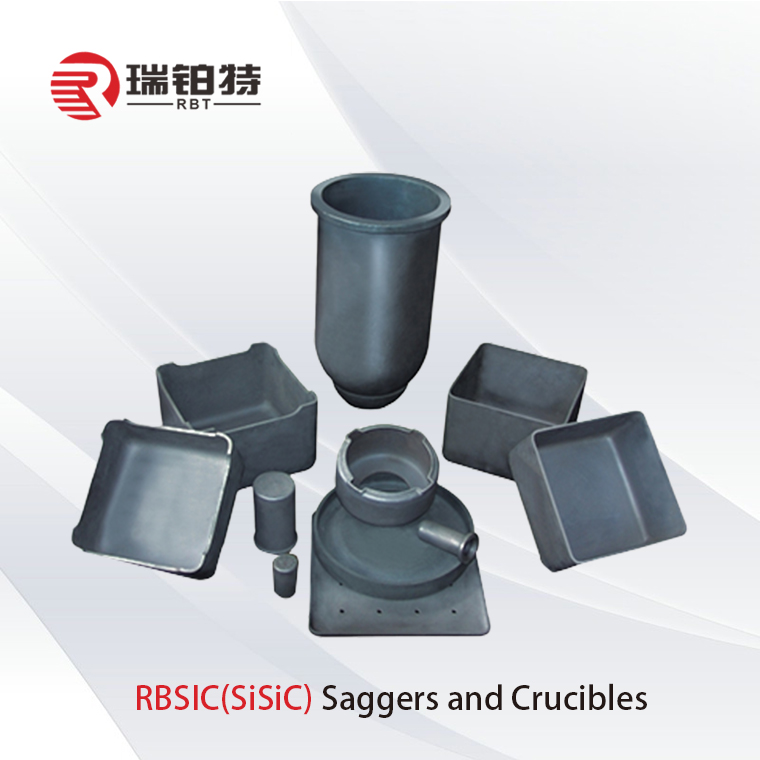

Details Images

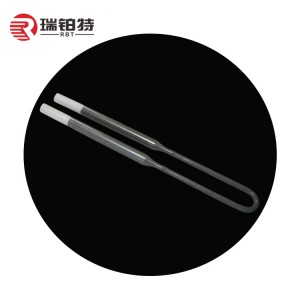

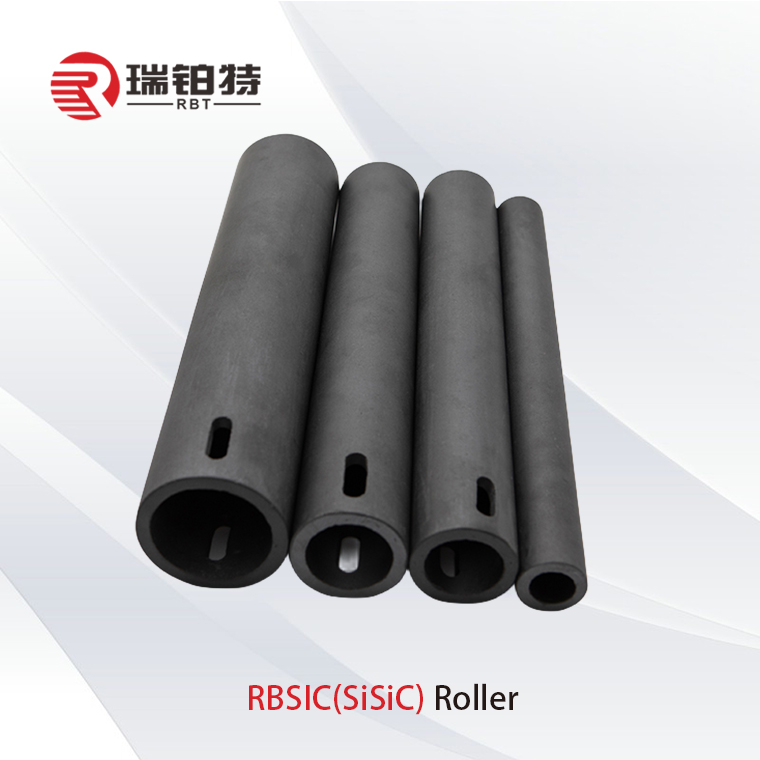

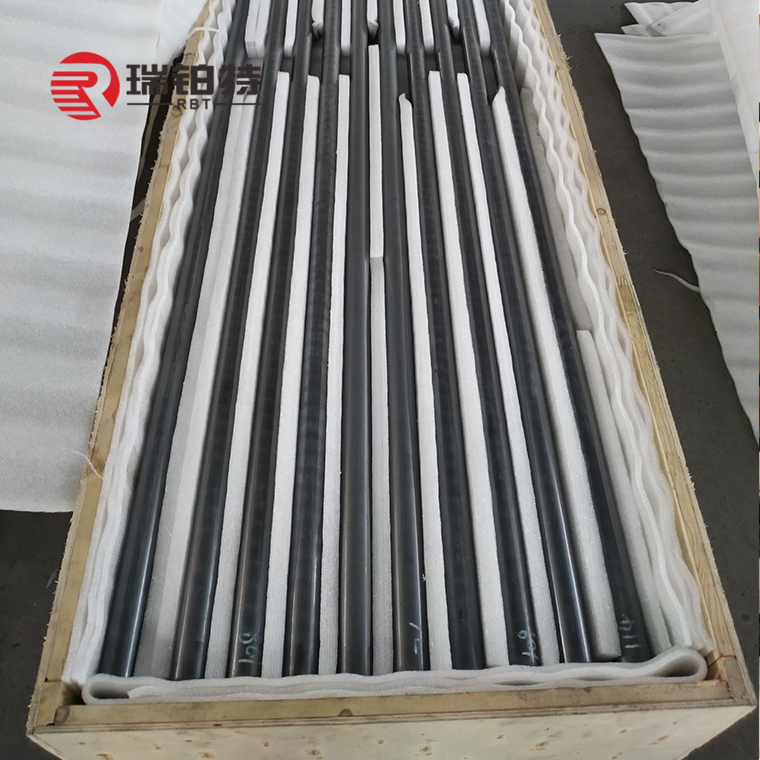

Feature:Iyo yakanakisa kemikari inoodza kupikisa yesilicon carbide roll rod inoita kuti ishande kwenguva yakareba munzvimbo yakasimba inoodza mhepo yelithium electric kiln, uye ine hupenyu hwakareba.

| Kutakura Kukwanisa kweRBSic (SiSiC) Rollers | |||

| SizeyeChikamu(mm) | WallUkobvu(mm) | ConcentratedKurodha(kg.m/L) | UniformlyDistributedKurodha(kg.m/L) |

| 30 | 5 | 43 | 86 |

| 35 | 5 | 63 | 126 |

| 35 | 6 | 70 | 140 |

| 38 | 5 | 77 | 154 |

| 40 | 6 | 97 | 197 |

| 45 | 6 | 130 | 260 |

| 50 | 6 | 167 | 334 |

| 60 | 7 | 283 | 566 |

| 70 | 7 | 405 | 810 |

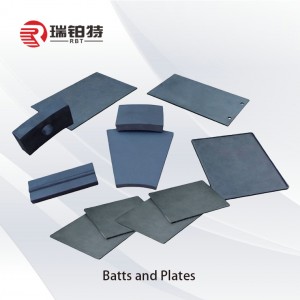

Application:Kiln yekushambira, tunnel kiln, roller kiln, uye imwe maindasitiri honi inotakura chimiro uye honi yerori inotakura zvigadzirwa.

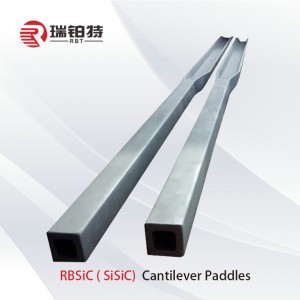

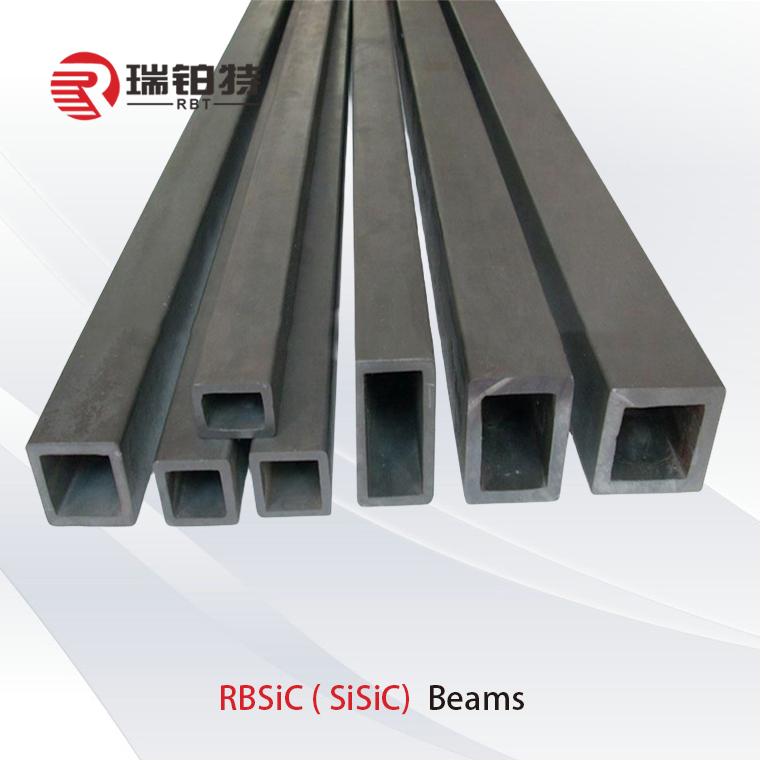

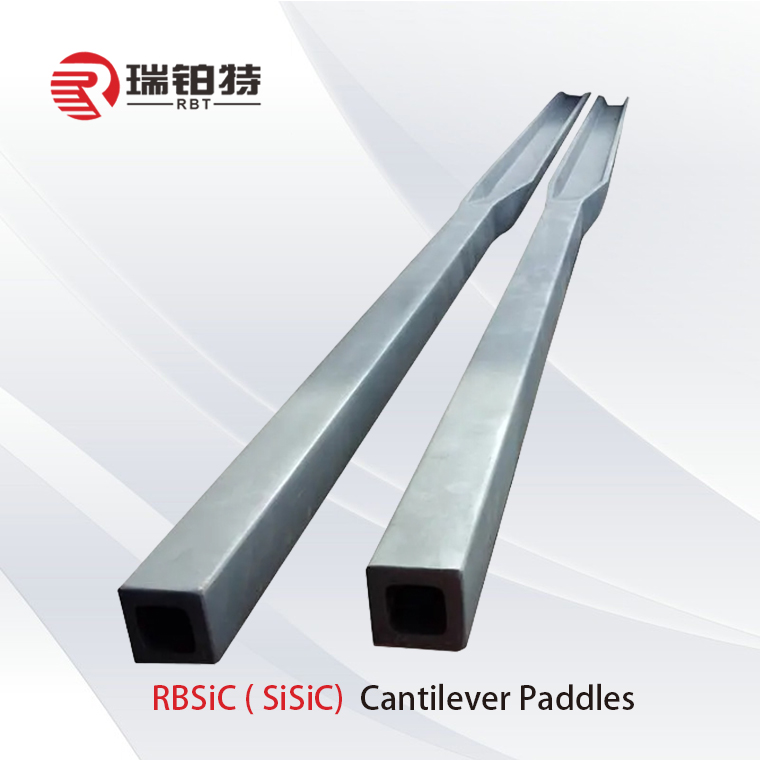

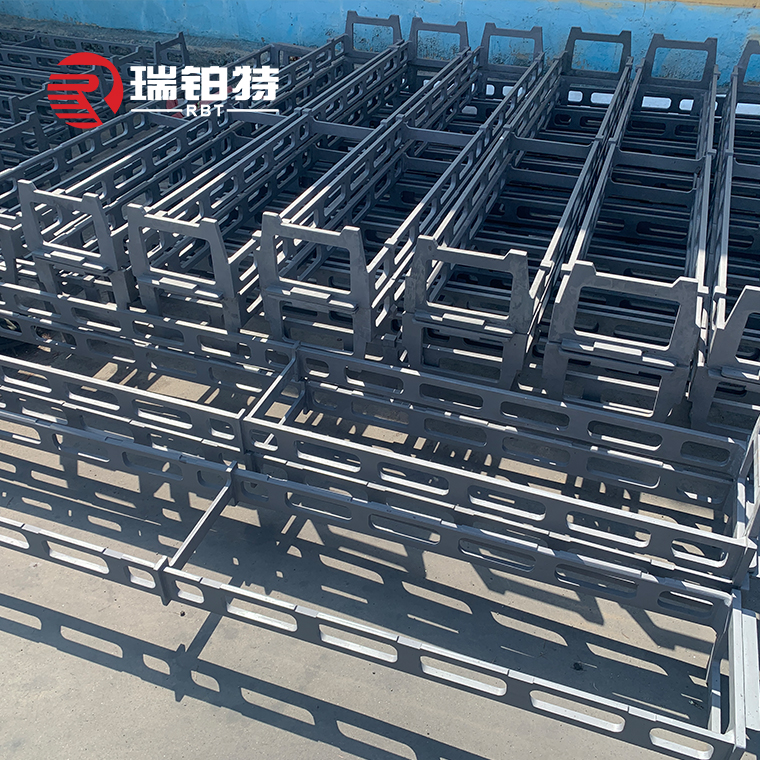

Feature:Silicon carbide square beam ine mabhenefiti ehukuru hwepamusoro tembiricha inotakura, yakanaka yekupisa conductivity, yakanyanya tembiricha inokambaira uye kuchengetedza simba.Ndiyo honi yakakodzera yelithium electric roller rod kiln, electronic ceramic powder, sanitary ware, daily ceramics, electric porcelain, refractory materials, foam ceramics, nemamwe maindasitiri.

| Kutakura Kukwanisa kweRBSic(SiSiC) Miti | ||||||

| Saizi yeChikamu (mm) | Wall Ukobvu (mm) | Concentrated Loading(kg.m/L) | Uniformly Distributed Loading(kg.m/L) | |||

| B Side | H Side | W Side | H Side | W Side | H Side | |

| 30 | 30 | 5 | 74 | 74 | 147 | 147 |

| 30 | 40 | 5 | 117 | 95 | 235 | 190 |

| 40 | 40 | 6 | 149 | 149 | 298 | 298 |

| 50 | 50 | 6 | 283 | 283 | 567 | 567 |

| 50 | 60 | 6 | 374 | 331 | 748 | 662 |

| 50 | 70 | 6 | 473 | 379 | 946 | 757 |

| 60 | 60 | 7 | 481 | 481 | 962 | 962 |

| 80 | 80 | 7 | 935 | 935 | 1869 | 1869 |

| 100 | 100 | 8 | 1708 | 1708 | 3416 | 3416 |

| 110 | 110 | 10 | 2498 | 2498 | 4997 | 4997 |

Burner Casing

Radiation Tube

Liners

Inotsigira

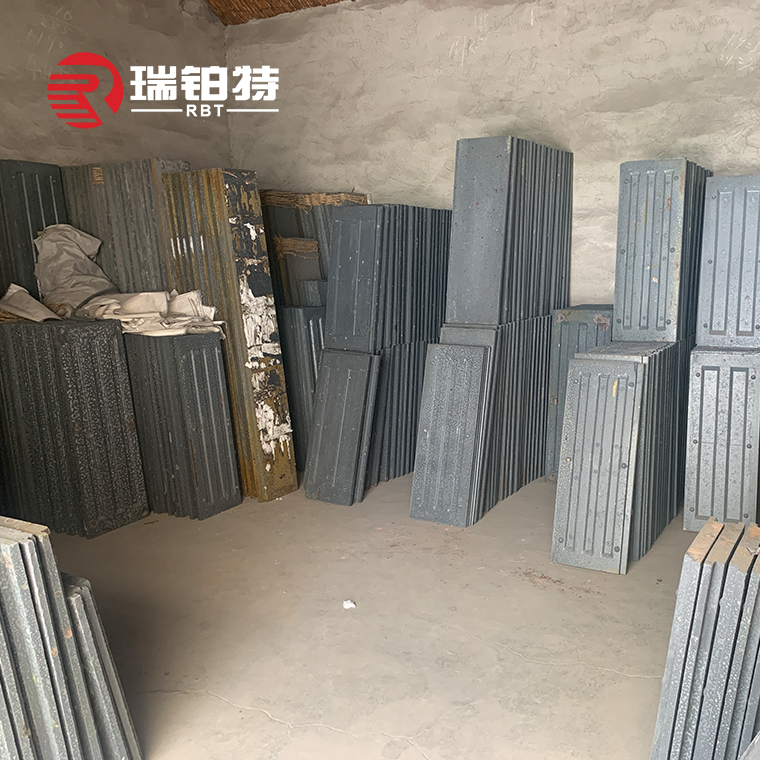

Package&Warehouse

Mibvunzo Inowanzo bvunzwa

Kuda rubatsiro?Iva nechokwadi chekushanyira maforamu edu ekutsigira mhinduro kumibvunzo yako!

Isu tiri mugadziri chaiye, fekitori yedu inyanzvi mukugadzira zvinhu zvekuramba kweanopfuura makore makumi matatu.Isu tinovimbisa kupa mutengo wakanakisa, yakanakisa pre-kutengesa uye mushure mekutengesa sevhisi.

Kune yega yega maitiro ekugadzira, RBT ine yakazara QC sisitimu yemakemikari ekuumbwa uye emuviri zvivakwa.Uye isu tichaedza zvinhu, uye chitupa chemhando ichaendeswa nenhumbi.Kana iwe uine zvakakosha zvinodiwa, isu tichaedza nepatinogona napo kuti tivape pekugara.

Zvichienderana nehuwandu, nguva yedu yekuendesa yakasiyana.Asi isu tinovimbisa kutumira nekukurumidza sezvinobvira nemhando yakavimbiswa.

Zvechokwadi, tinopa sampuli dzemahara.

Hongu, hongu, unogamuchirwa kushanyira kambani yeRBT uye zvigadzirwa zvedu.

Iko hakuna muganho, isu tinogona kupa yakanakisa zano uye mhinduro zvinoenderana nemamiriro ako.

Tave tichigadzira zvinhu zvekuramba kweanopfuura makore makumi matatu, tine rutsigiro rwakasimba rwehunyanzvi uye ruzivo rwakapfuma, tinokwanisa kubatsira vatengi kugadzira kilns dzakasiyana uye kupa imwe-stop service.