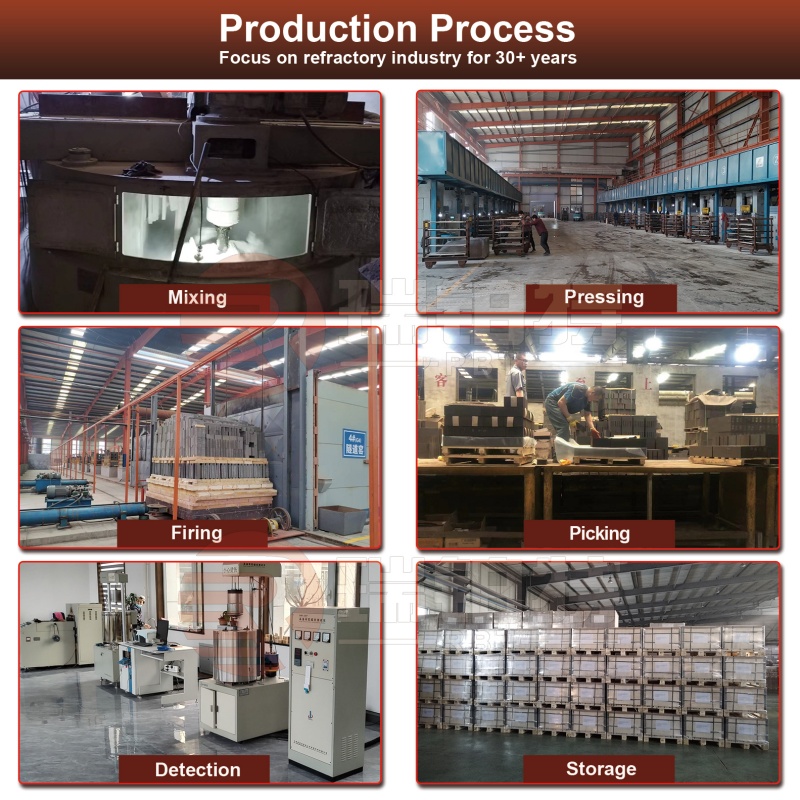

Munzvimbo dzemaovheni emumaindasitiri anopisa zvakanyanya (akadai sema converters ekugadzira simbi, ma ladle, uye maovheni ekuputika),zvidhinha zve magnesium kabhoniZvidhinha izvi zvinoonekwa sezvinhu zvinodzivirira ngura, nekuda kwekudzivirira kwavo ngura, kugadzikana pakupisa kwakanyanya, uye kuramba kupisa. Maitiro ekugadzira zvidhinha izvi musanganiswa wakasimba wetekinoroji uye kunyatsojeka—danho rega rega rinotarisa zvakananga mhando yechigadzirwa chekupedzisira. Pazasi, tinokuratidzai nzira yakazara yekugadzira zvidhinha zve magnesium carbon, tichiratidza kuti tinoona sei kuti dhinha rega rega rinosangana nezvinodiwa zveindasitiri.

1. Kusarudzwa Kwezvinhu Zvisina Kugadzirwa: Hwaro hweZvidhinha zveMagnesium Carbon zvemhando yepamusoro

Hunhu hwezvinhu zvakagadzirwa ndiyo nzira yekutanga yekudzivirira mashandiro ezvidhinha zve magnesium carbon. Tinotevedzera mitemo yekusarudza yakasimba kuti tive nechokwadi chekuti chikamu chimwe nechimwe chinosangana nezvinodiwa zvepamusoro:

Magnesia Aggregate Yakachena Zvikuru:Tinoshandisa fused magnesia kana sintered magnesia ine MgO inodarika 96%. Izvi zvinopa zvidhinha simba rakasimba rekudzivirira kupisa kwakanyanya uye kuramba ngura, zvichibudirira kutsungirira kuputsika kwesimbi yakanyungudutswa uye slag mumaoven.

Kabhoni Yepamusoro-soro Chitubu:Graphite yechisikigo ine kabhoni inosvika 90%+ inosarudzwa. Chimiro chayo chakagadzirwa nematanda chinowedzera simba rekudzivirira kupisa kwezvidhinha, zvichideredza njodzi yekutsemuka nekuda kwekuchinja kukuru kwekushisa panguva yekushanda kwechoto.

Bhandi Repamusorosoro:Phenolic resin (yakagadziriswa kuti irambe ichipisa zvakanyanya) inoshandiswa sechinobatanidza. Inoita kuti magnesia negraphite zvibatane zvakasimba, uku ichidzivirira kuputika kana kuora kana tembiricha yakakwira, izvo zvingakanganisa kusimba kwezvidhinha.

Zvimwe Zvinowedzera:Zvishomanana zve antioxidants (zvakaita se aluminium powder, silicon powder) uye zvinhu zvinobatsira pakugadzira sintering zvinowedzerwa kudzivirira graphite oxidation uye kuvandudza density yezvidhinha. Zvese zvinoshandiswa zvinoedzwa katatu kuti zvibvise tsvina inogona kuderedza kushanda zvakanaka.

2. Kupwanya uye Kuunganidza: Kudzora Saizi yeZvidimbu Zvakanyatsonaka zveMaumbirwo Akafanana

Kugoverwa kwehukuru hwezvidimbu zvakafanana kwakakosha pakuona kuti zvidhinha zve magnesium carbon zvakabatana uye zvine simba. Danho iri rinotevedzera mitemo yakasimba yehunyanzvi:

Maitiro Ekupwanya:Kutanga, mabhuroko makuru e magnesia ne graphite zvinopwanywa kuita zvidimbu zvidiki uchishandisa majaw crushers uye ma impact crushers. Kumhanya kwekupwanya kunodzorwa pa 20-30 rpm kudzivirira kupisa zvakanyanya uye kukuvara kwechimiro chezvinhu zvakagadziriswa.

Kuongorora uye Kuronga:Zvinhu zvakapwanywa zvinovharwa kuburikidza nema "multi-layer vibrating screens" (ane mesh sizes ye5mm, 2mm, uye 0.074mm) kuti zviparadzaniswe kuita "coarse aggregates" (3-5mm), "medium aggregates" (1-2mm), "fine aggregates" (0.074-1mm), uye "ultrafine powders" (<0.074mm). Kukanganisa kwe "particle size" kunodzorwa mukati me ±0.1mm.

Kubatanidzwa kwegranule:Saizi dzakasiyana dzezvimedu zvinosanganiswa mumuchina wekusanganisa unomhanya zvakanyanya kwemaminitsi gumi kusvika gumi nemashanu nekumhanya kwe800 rpm. Izvi zvinoita kuti bhora rega rega remagranule rive nekugadzirwa kwakafanana, zvichigadzira hwaro hwehuwandu hwezvidhinha zvakaenzana.

3. Kusanganisa nekukanya: Kuwana Kubatana Kwakasimba Pakati Pezvikamu

Danho rekusanganisa nekukanya rinoona simba rekubatanidza zvinhu zvakagadzirwa. Tinoshandisa michina yekusanganisa miviri yakapinza uye tinodzora mamiriro ezvinhu:

Kusanganisa Zvinhu Zvakaoma Pamberi:Zvimedu zvakakora, zvepakati, uye zvakapfava zvinotanga zvasanganiswa zvakaoma kwemaminitsi mashanu kuitira kuti chikamu chimwe nechimwe chive chakaenzana. Danho iri rinodzivisa kuwanda kwekabhoni kana magnesia munzvimbo, izvo zvinogona kukonzera kusiyana kwekushanda.

Kuwedzera Binder uye Kneading:Phenolic resin yakagadziriswa (inopiswa kusvika 40-50℃ kuti iite zviri nani) inowedzerwa kumusanganiswa wakaoma, yozoteverwa nemaminitsi 20-25 ekukanya. Tembiricha yemusanganiswa inochengetwa pa55-65℃, uye kumanikidzwa kunodzorwa pa0.3-0.5 MPa—izvi zvinoita kuti binder iputire zvakakwana chidimbu chimwe nechimwe, ichigadzira chimiro chakasimba che "magnesia-graphite-binder".

Kuedzwa kweKusachinja-chinja:Mushure mekukanya, kuenzana kwemusanganiswa kunoedzwa maminetsi gumi ega ega. Kuenzana kwakakodzera i30-40 (kunoyerwa nemita yekuenzanisa yakajairika); kana yakaoma zvakanyanya kana kuti yakanyorova zvakanyanya, chiyero chebinder kana nguva yekukanya inogadziriswa panguva chaiyo.

4. Kugadzira Press: Kugadzira Pressure Yakanyanya Kuti Ive Nehuwandu Uye Simba

Kugadzira press ndiyo danho rinopa magnesium carbon bricks chimiro chadzo chekupedzisira uye rinoita kuti zvive nyore kuona kuti magnesium iri kurema zvakanyanya. Tinoshandisa automatic hydraulic presses ine simba rekutonga kudzvanywa kwakakodzera:

Kugadzirira Foroma:Zviumbwa zvesimbi zvakagadzirwa nemaoko (zvinoenderana nezvinodiwa nevatengi zvehukuru hwezvidhinha, zvakaita se230×114×65mm kana saizi dzakagadzirwa nemaoko) zvinocheneswa uye zvinoputirwa nechinhu chinosunungura zvinhu kuti musanganiswa usanamatira pachiumbwa.

Kudzvanya-Kudzvanya Kwakanyanya:Musanganiswa wakakanyiwa unodururwa muchimiro, uye hydraulic press inoshandisa kumanikidzwa kwe30-50 MPa. Kumhanya kwekudzvanya kunoiswa pa5-8 mm/s (kudzvanya zvishoma nezvishoma kubvisa mabubble emhepo) uye kunochengetwa kwemasekonzi 3-5. Maitiro aya anoita kuti huwandu hwezvidhinha husvike pa2.8-3.0 g/cm³, neburi riri pasi pe8%.

Kubvisa uye Kuongorora:Mushure mekudzvanya, zvidhinha zvinobviswa otomatiki uye zvinoongororwa kuti hazvina kunaka pamusoro (sekutsemuka, mipendero isina kuenzana). Zvidhinha zvine zvikanganiso zvinorambwa pakarepo kuti zvisapinde muchirongwa chinotevera.

5. Kurapa Kupisa (Kuchenesa): Kuvandudza Kubatana Kwebhainda uye Kugadzikana

Kurapa kupisa (kupisa) kunosimbisa kubatana kwebinder uye kunobvisa zvinhu zvinoputika kubva muzvidhinha. Tinoshandisa makinu emumatune ane tembiricha chaiyo:

Kupisa nematanho: Zvidhinha zvinoiswa muchoto chemugero, uye tembiricha inokwidzwa nematanho:

20-80℃ (maawa maviri):Hunyoro hwepamusoro hunobuda;

80-150℃ (maawa mana):Kurudzira kucheneswa kwe resin pakutanga;

150-200℃ (maawa matanhatu):Kubatanidza nekugadzika resin zvakakwana;

200-220℃ (maawa matatu):Simbisa chimiro chezvidhinha.

Mwero wekupisa unodzorwa pa10-15℃/awa kudzivirira kutsemuka nekuda kwekumanikidzwa kwekupisa.

Kubviswa Kwezvinhu Zvisingatani Kuoma:Munguva yekugadzika, zvinhu zvinoshanduka-shanduka (senge ma small-molecule resins) zvinoburitswa kuburikidza ne oksijeni ye oksijeni, zvichiita kuti chimiro chemukati chezvidhinha chive chakasimba uye chisina maburi.

Maitiro Ekutonhodza: Mushure mekuomesa, zvidhinha zvinotonhodzwa kusvika patembiricha yemukamuri nechiyero che20℃/awa. Kutonhodza nekukurumidza kunodzivirirwa kudzivirira kukuvara kwekupisa.

6. Kuongororwa Kwemhando Yepamusoro Mushure meKugadzirwa: Kuve nechokwadi chekuti Chidhinha Chese Chinosangana Nezvinodiwa

Danho rekupedzisira rekugadzira rinotarisa pakugadzirisa nemazvo uye kuyedzwa kwemhando yepamusoro kuti ive nechokwadi chekuti dhinha rega rega re magnesium carbon rinosangana nezvinodiwa zvekushandiswa mumaindasitiri:

Kukuya uye Kuchekerera:Zvidhinha zvine mipendero isina kuenzana zvinokuyiwa uchishandisa michina yekukuya yeCNC, zvichiita kuti chikanganiso chive mukati me ±0.5mm. Zvidhinha zvine chimiro chakasarudzika (senge zvidhinha zvakaita searc zvevashanduri) zvinogadziriswa uchishandisa nzvimbo dzekugadzira madziro dzine axis 5 kuti dzienderane necurve yemukati mefurnace.

Kuongororwa Kwemhando Yese:Boka rega rega rezvidhinha rinoedzwa kashanu:

Kuwanda uye Kuedza Kwekuyera:Uchishandisa nzira yeArchimedes, iva nechokwadi chekuti huwandu hwemvura hwakaita ≥2.8 g/cm³ uye kuti mvura yacho yakakora ≤8%.

Kuedza Simba Rinomanikidzwa:Edza simba rekudzvanya kwezvidhinha (≥25 MPa) uchishandisa muchina wekuyedza wepasi rose.

Muedzo weKuramba Kupisa Kwekupisa:Mushure menguva gumi dzekupisa (1100℃) uye kutonhodza (tembiricha yemukamuri), tarisa kana paine mitswe (hapana mitswe inoonekwa inobvumidzwa).

Muedzo weKuramba Kuora:Tevedzera mamiriro echoto kuti uedze kuramba kwezvidhinha pakukanganiswa nekukanganiswa kwetsvina yakanyungudutswa (chiyero chekukukurwa kwevhu ≤0.5mm/awa).

Kuongorora Kuumbwa Kwemakemikari:Shandisa X-ray fluorescence spectrometry kuti uone zviri muMgO (≥96%) uye zviri mucarbon (8-12%).

Kurongedza uye Kuchengeta:Zvidhinha zvakakodzera zvinoiswa mumabhokisi asinganyungudike kana mapaleti emapuranga, nefirimu risinganyungudike rakaputirwa kuti zvisanyungudike panguva yekufambisa. Pakeji yega yega yakanyorwa nhamba yebatch, zuva rekugadzirwa, uye chitupa chekuongorora hunhu kuti chionekwe zvakanaka.

Sei Uchifanira Kusarudza Magnesium Carbon Bricks Yedu?

Maitiro edu ekugadzira zvinhu (kubva pakusarudza zvinhu zvisina kugadzirwa kusvika pakugadzirisa) anoita kuti zvidhinha zvedu zve magnesium carbon zvishande zvakanaka mumaovheni emumaindasitiri anodziya zvakanyanya. Zvingave zvezvigadziriso zvesimbi, madhishi, kana mimwe midziyo inodziya zvakanyanya, zvigadzirwa zvedu zvinogona:

Ramba uchitsungirira tembiricha inosvika 1800℃ pasina kupfava kana kuchinja.

Dzivisai kukanganiswa kwesimbi yakanyungudutswa uye slag, zvichiita kuti hupenyu hwechoto huwedzere ne30%+.

Deredzai nguva yekugadzirisa uye mari yekugadzira yevatengi.

Tinopa mhinduro dzakagadzirwa zvinoenderana nerudzi rwechoto chenyu, saizi, uye mamiriro ekushanda. Taura nesu nhasi kuti udzidze zvakawanda nezvemaitiro edu ekugadzira zvidhinha zve magnesium carbon kana kuti uwane mutengo wemahara!

Nguva yekutumira: Gumiguru-29-2025