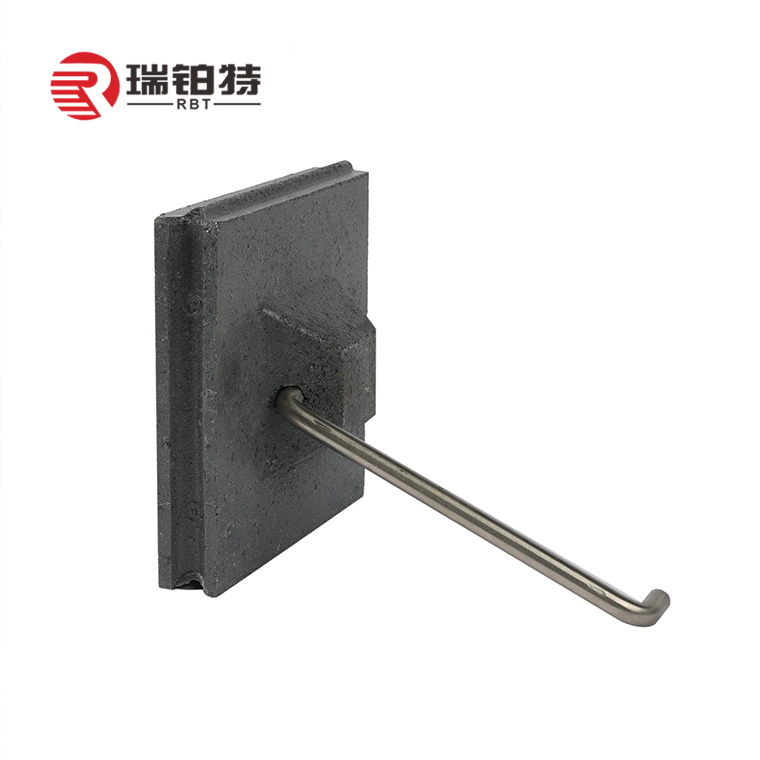

Silicon Carbide Dryer Lgniter

Zvikamu zveZvigadzirwa

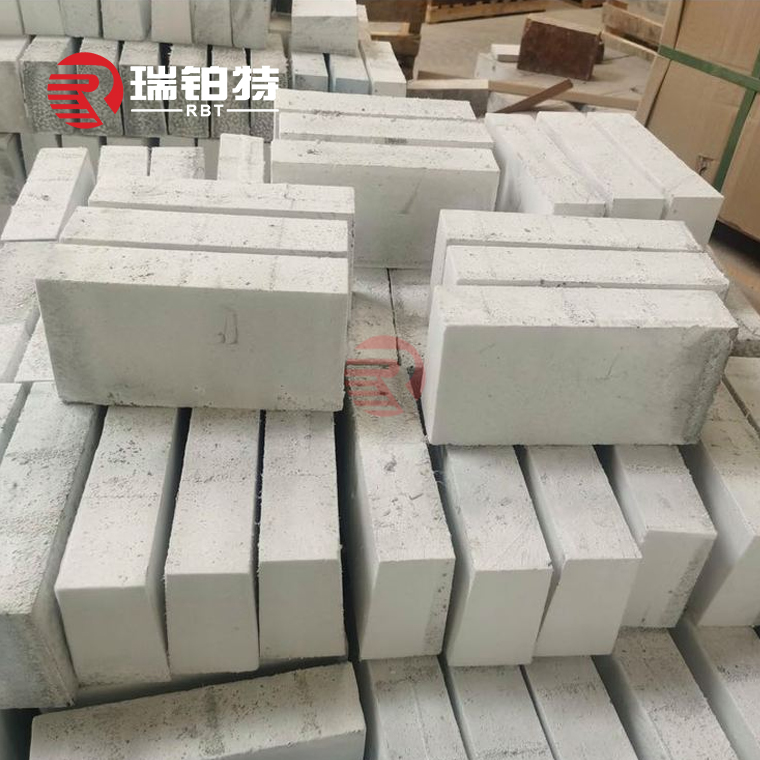

1. Zvigadzirwa zvesilicon carbide zvinogadzirwa neReaction sintered (RBSiC Products)

Reaction bonded silicon carbide (RBSiC) imhando yepamusoro yeceramic inogadzira silicon carbide bonding phase nekuita free carbon ne liquid silicon pasi pemamiriro ekupisa kwakanyanya. Zvikamu zvayo zvekutanga zvinosanganisira silicon carbide (SiC) matrix uye free silicon (Si). Yekutanga inopa hunhu hwakanaka hwemakanika, kuramba kupfeka uye kugadzikana kwekupisa kwakanyanya,

nepo yekupedzisira ichizadza maburi ari pakati pezvikamu zvesilicon carbide kuti iwedzere kuwanda uye kusimba kwechimiro chezvinhu.

(1) Hunhu:

Kugadzikana kwekupisa kwakanyanya:Tembiricha yepamusoro yekushandisa ndeye 1350℃.

Kuramba kupfeka uye kuramba ngura:Yakakodzera kushanda mumamiriro ekunze akaomarara ekupisa kwakanyanya, acid, alkali uye simbi yakanyungudutswa.

Kupisa kwakanyanya uye kuwedzera kwekupisa kwakaderera:Kufambiswa kwemhepo mukupisa kwakakwira kusvika pa120-200 W/(m·K), uye chiyero chekuwedzera kwekupisa chakaenzana ne4.5×10⁻⁶ K⁻¹ chete, izvo zvinodzivirira kupisa kutsemuka uye kuneta kwekupisa.

Anti-oxidation:Rutivi rwakasimba rwekudzivirira silica runogadzirwa pamusoro pemvura pakupisa kwakanyanya kuti ruwedzere hupenyu hwebasa.

(2) Zvigadzirwa Zvikuru:

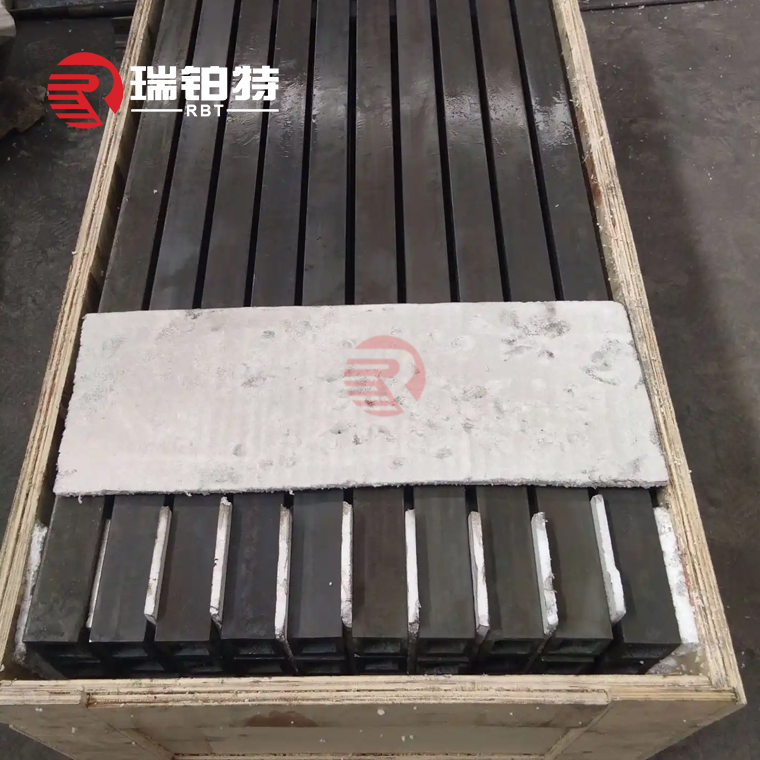

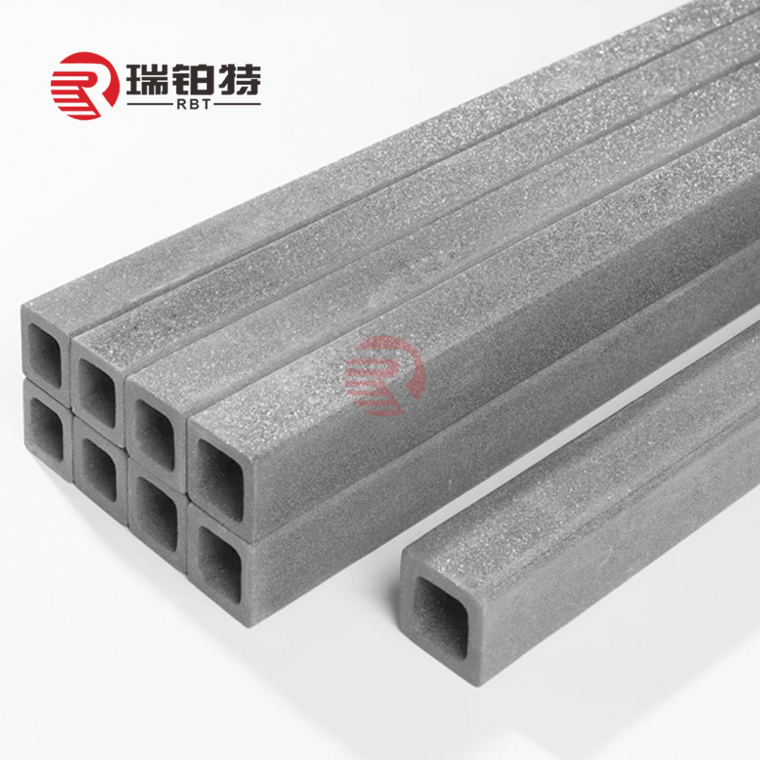

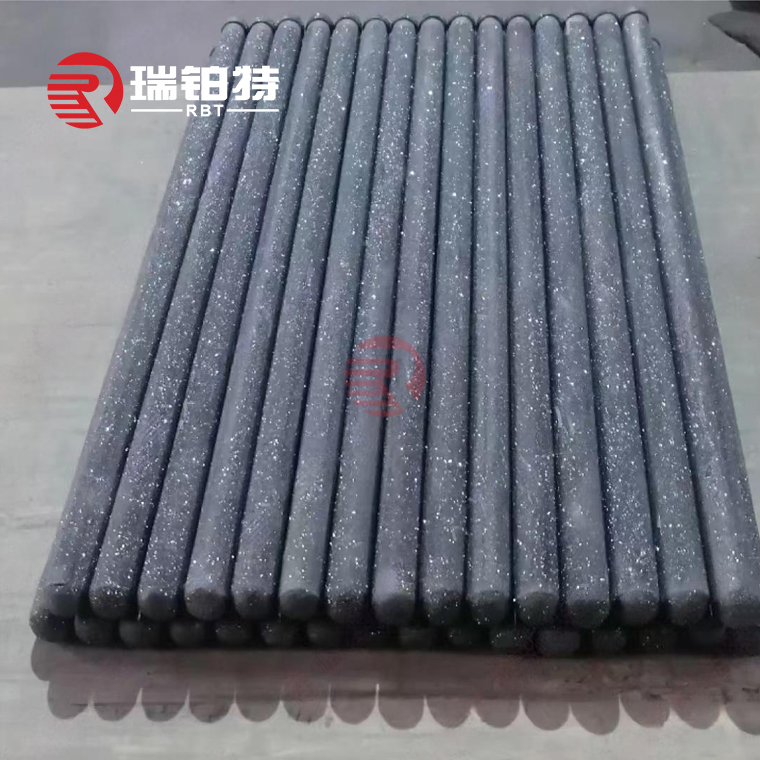

Silicon carbide beam:Inoshandiswa pakuvaka makiln emugero, makiln emuchina wekufambisa ngarava nemamwe makiln emaindasitiri, ane huremu hwakanaka hwekupisa kwakanyanya.

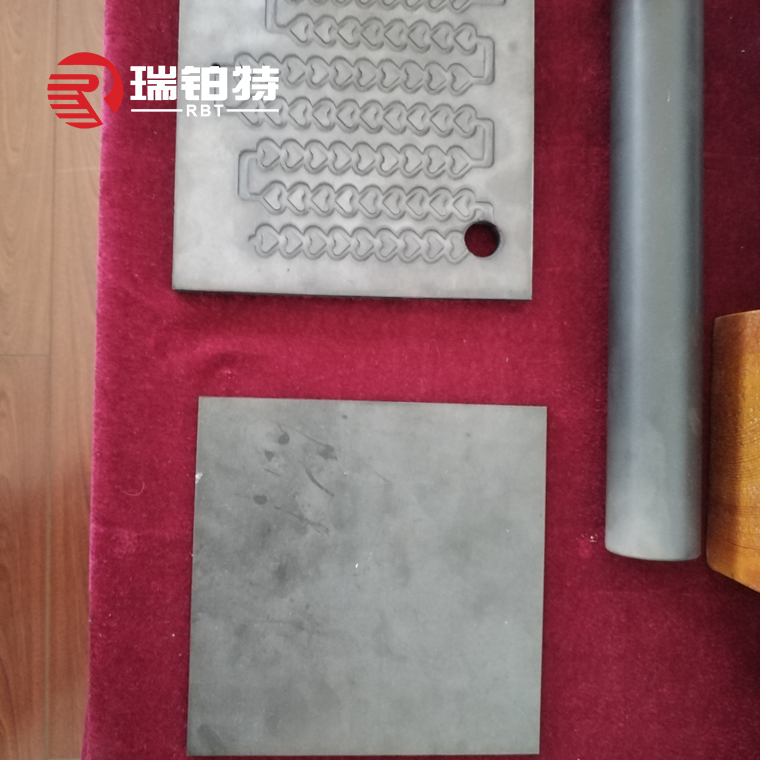

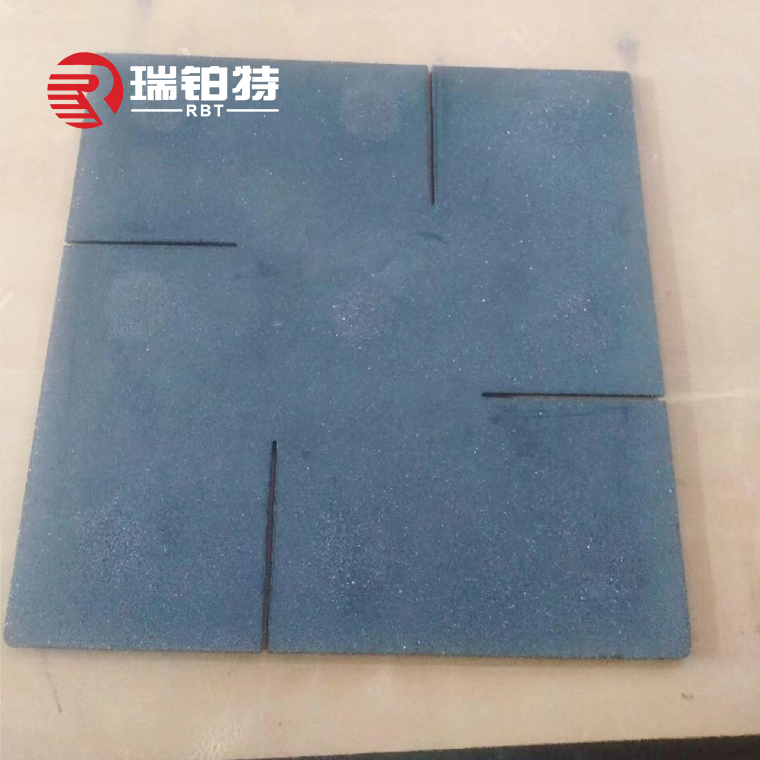

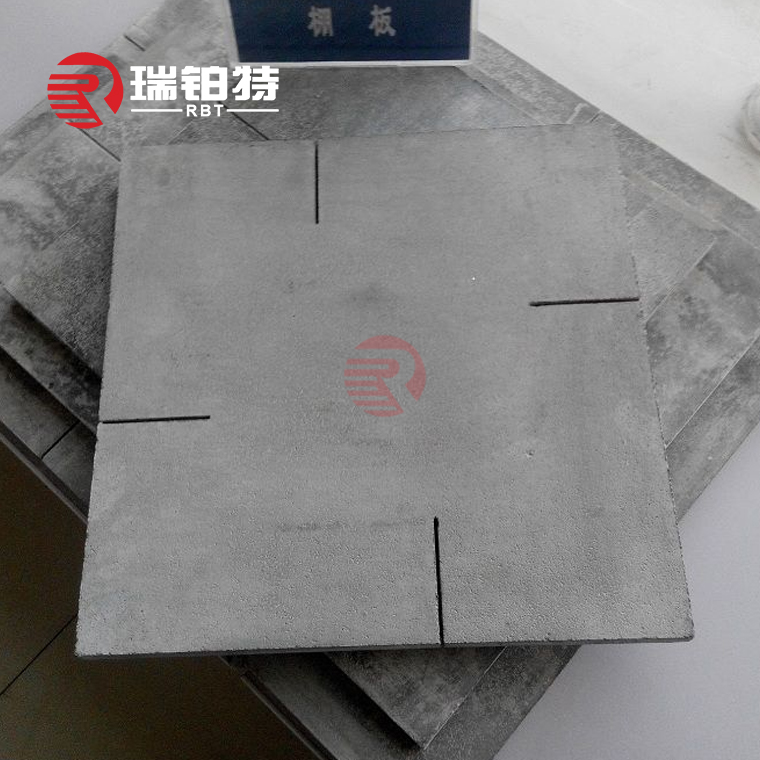

Silicon carbide plate:inoshandiswa pazvinhu zvinoramba kurira mumaovheni, zvine hunhu hwekubatana kwe oxide.

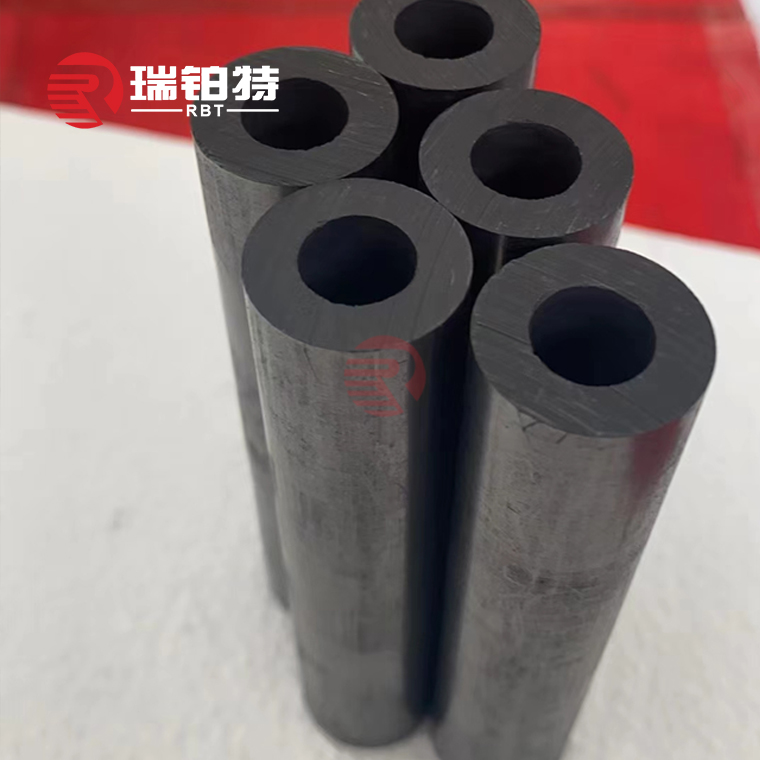

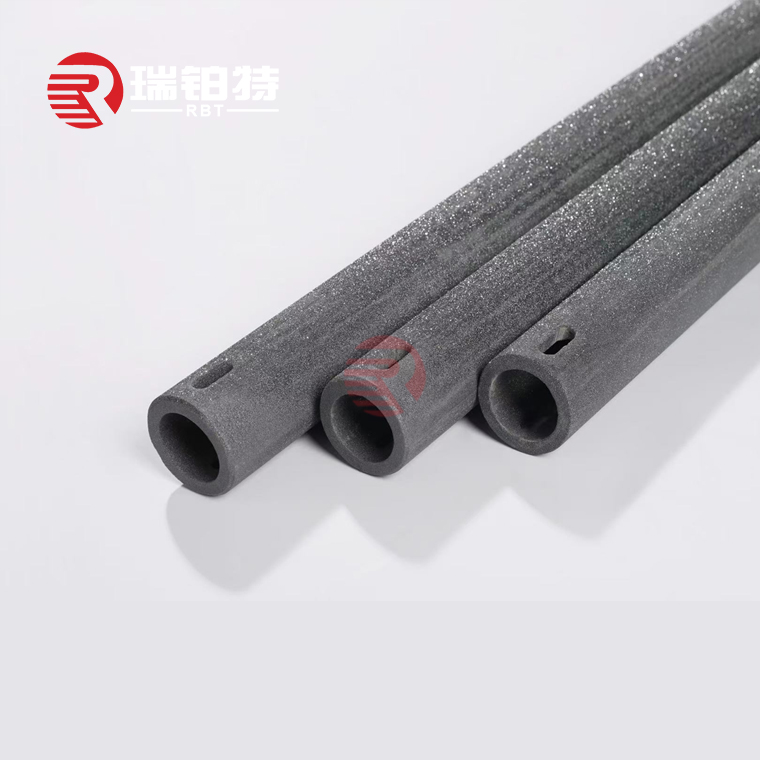

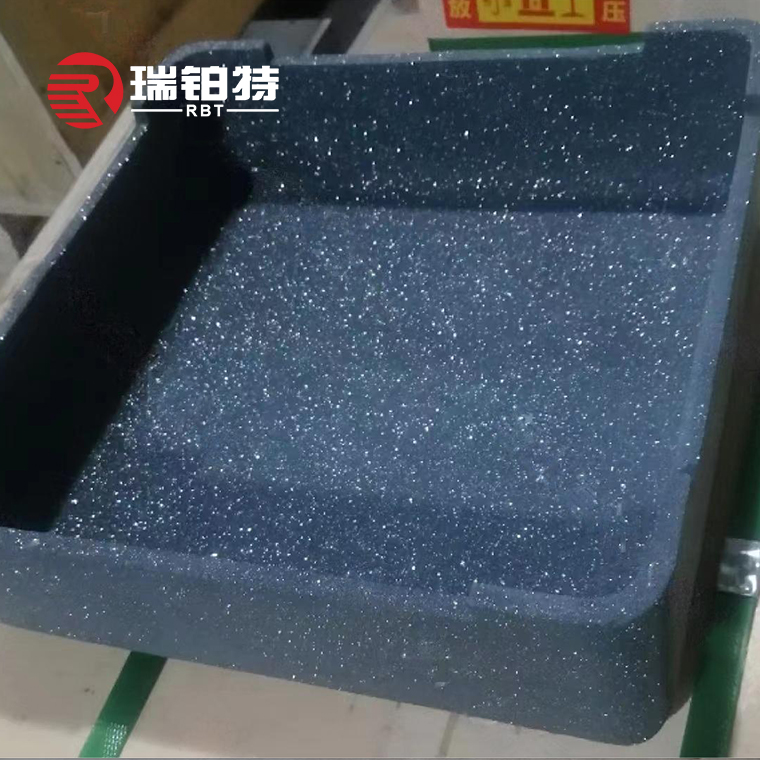

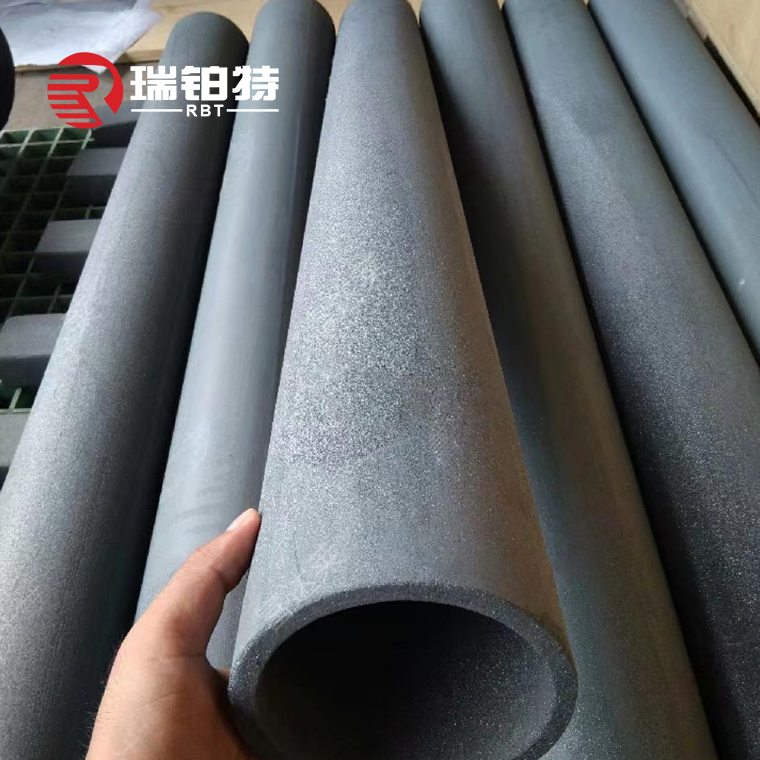

Pombi yesilicon carbide:inoshandiswa pakuisa mapaipi nemagaba munzvimbo dzakasiyana-siyana dzinopisa zvakanyanya.

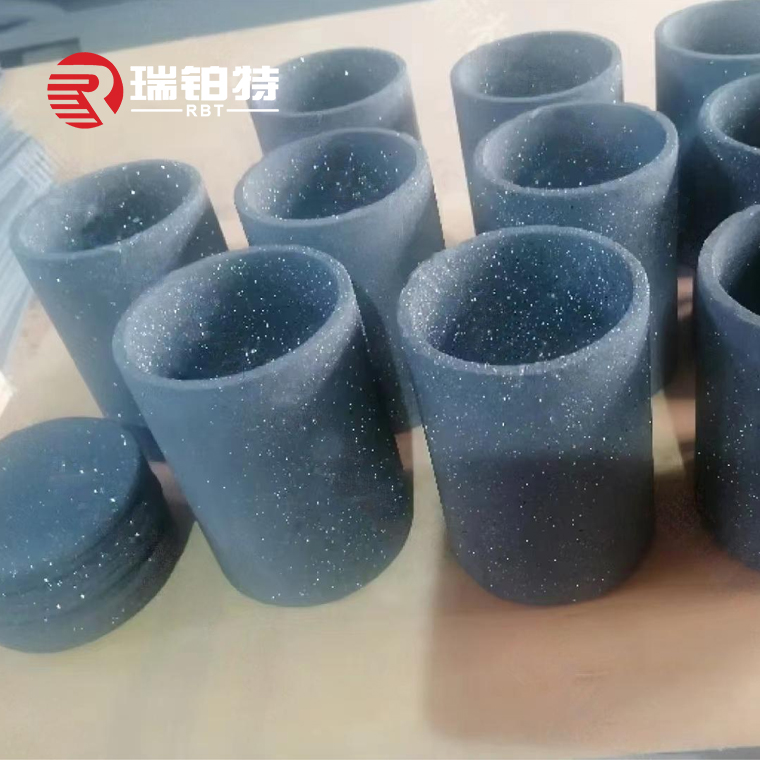

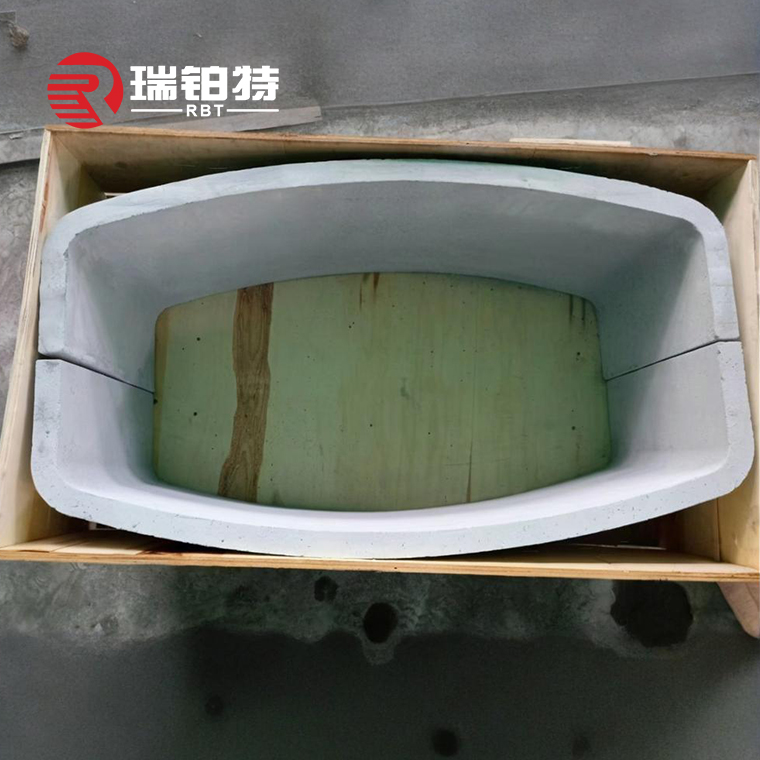

Silicon carbide crucible uye sagger:inoshandiswa pakunyungudutsa uye kuchengetera zvinhu pakupisa kwakanyanya.

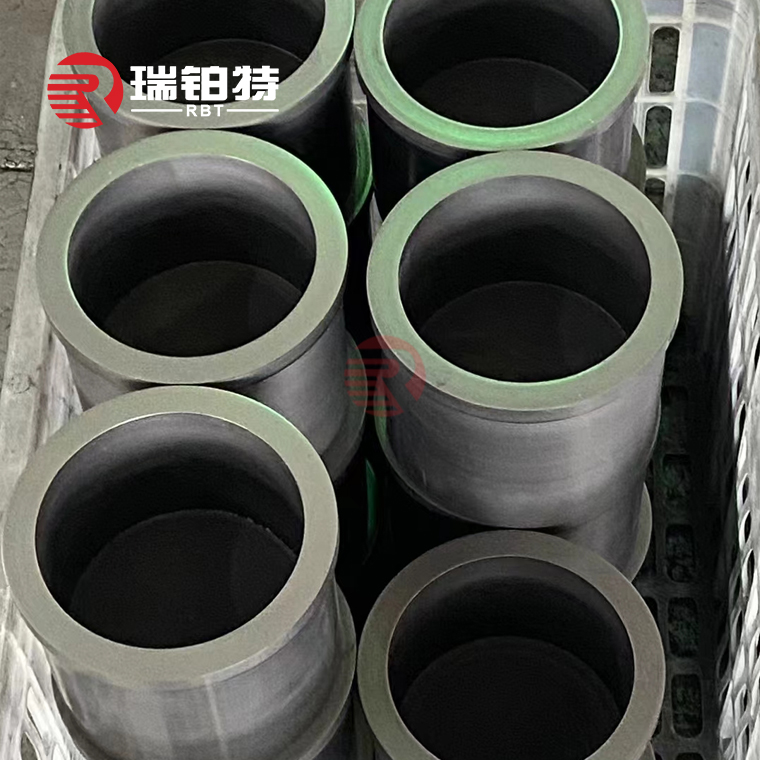

Mhete yesimbi yesilicon carbide:Inoshandiswa zvakanyanya muminda yemotokari, indasitiri yendege nemakemikari, uye inogona kuchengetedza kushanda kwakavimbika kwekuvhara munzvimbo dzinopisa zvakanyanya uye dzakamanikidzwa zvakanyanya.

Chinotenderera chekabhoni chesilicon:inoshandiswa kumaovheni anotenderera, ine hunhu hwekudzivirira oxidation, simba reflexural rinopisa zvakanyanya uye hupenyu hurefu hwebasa.

Mapaipi ekutonhodza eSilicon carbide:inoshandiswa kunzvimbo yekutonhodza makinu anotenderera, ine simba rakanaka rekudzivirira zvakanyanya

kutonhora nekupisa.

Silicon carbide bunner nozzle:inoshandiswa pamafuta akasiyana-siyana, gasi nedzimwe nzvimbo dzemaindasitiri, ine hunhu hwekudzivirira kutonhora zvakanyanya uye kupisa, kudzivirira kupera, kudzivirira kupisa kwakanyanya, nezvimwewo.

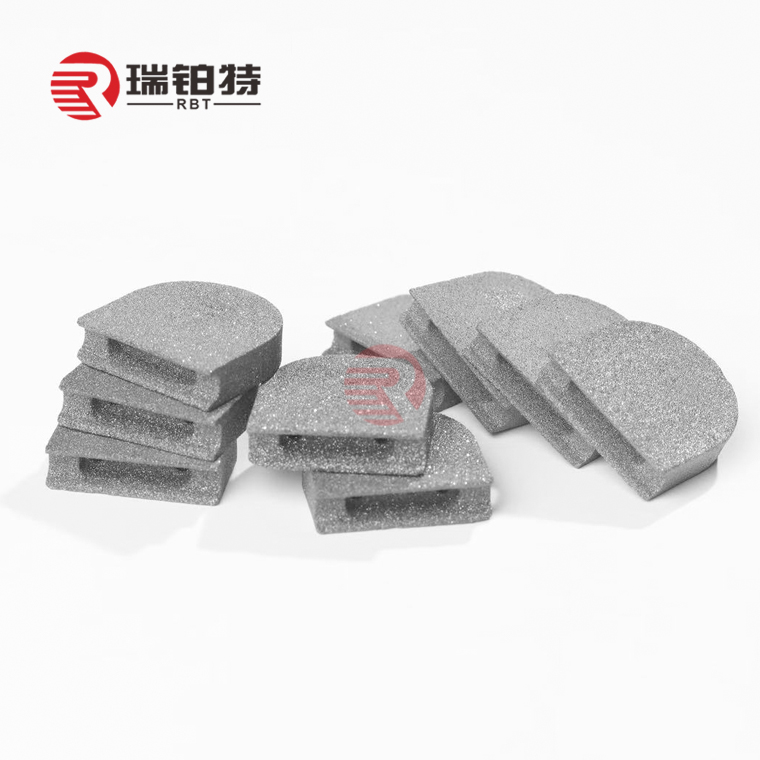

Zvikamu zvakagadzirwa nechimiro chakasarudzika:Kugadzirwa kwakagadzirwa kwezvikamu zvakasiyana-siyana zvine chimiro chakakosha zvichienderana nezvinodiwa nevatengi, zvakaita semaplate akaita sehove, tsvimbo dzinorembera, zvikamu zvekutsigira, nezvimwewo.

Mifananidzo Yemashoko

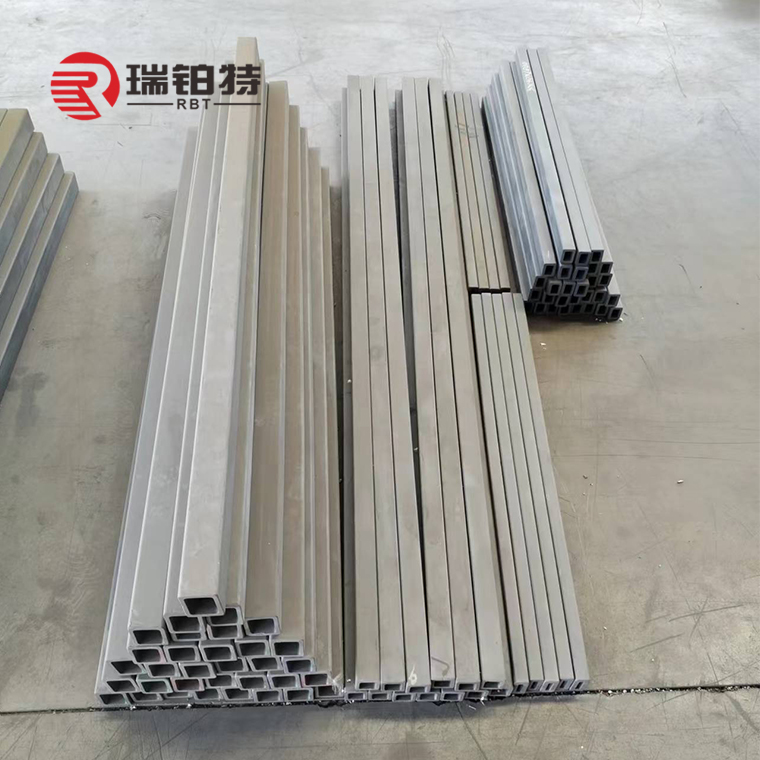

Beam reSilicon Carbide

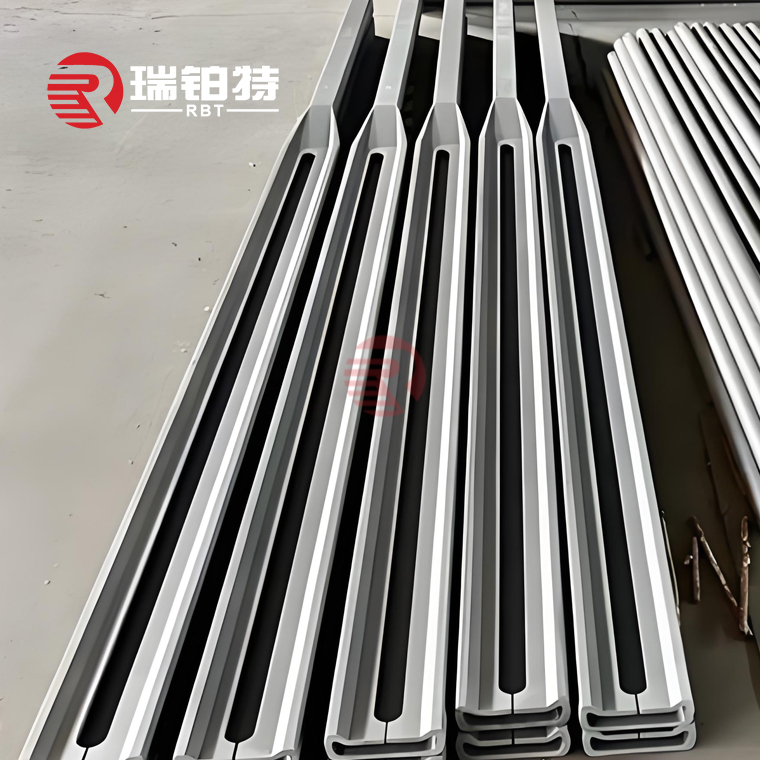

Chidzitiro cheSilicon Carbide Cantilever

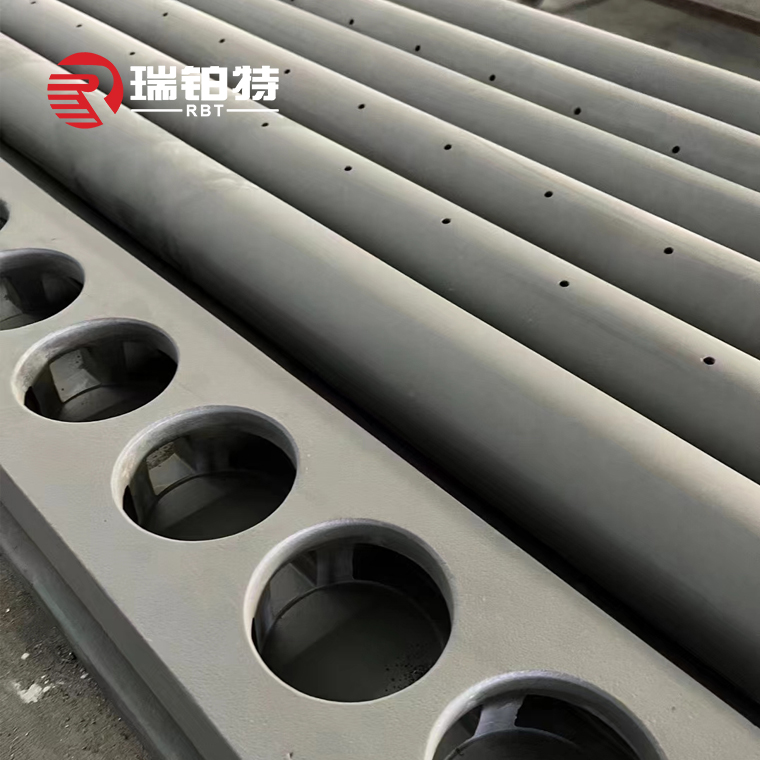

Silicon Carbide buri

Silicon Carbide Burner Tube

Mapaipi Ekutonhodza eSilicon Carbide

Silicon Carbide buri

Chikomboredzo cheSilikoni Carbide Chikepe

Mucheka usingapfeki

Chikepe cheSilicon Carbide Wafer

Index yeChigadzirwa

| Zvigadzirwa zveRBSiC(SiSiC) | ||

| Chinhu | Chikamu | Data |

| Kupisa Kwakanyanya Kwekushandisa | ℃ | ≤1350 |

| Kuwanda kwevanhu | g/cm3 | ≥3.02 |

| Vhura Porosity | % | ≤0.1 |

| Simba Rekukombama | Mpa | 250(20℃); 280(1200℃) |

| Modulus yeElasticity | Gpa | 330(20℃); 300(1200℃) |

| Kufambisa kwekupisa | W/mk | 45 (1200℃) |

| Kuwedzerwa kweThermal Coefficient | K-1*10-6 | 4.5 |

| Kuoma kwaMoh | | 9.15 |

| Inodzivirira Alkaline neAcid | | Zvakanakisa |

2. Zvigadzirwa zvesilicon carbide zvisina kumanikidzwa (SSiC Products)

Zvigadzirwa zvesilicon carbide isina kumanikidzwa imhando yezvinhu zveceramic zvemhando yepamusoro zvakagadzirwa nenzira yekusvina isina kumanikidzwa. Chikamu chayo chikuru isilicon carbide (SiC), uye chikamu chakati chezvinowedzera zvinowedzerwa. Kuburikidza netekinoroji yepamusoro yeceramic, inogadzirwa kuita ceramics dzisina maburi, dzisina musono, uye dzisina kushushikana.

(1) Hunhu:

Kudzivirira kupisa kwakanyanya:kushandiswa kwakajairika pa1800℃;

Kupisa kwakanyanya:yakaenzana nekupisa kwegraphitezvinhu;

Kuomarara kwakanyanya:kuomarara kuri kwechipiri kune dhaimani ne cubic boron nitride;

Kuramba ngura:asidhi yakasimba uye alkali yakasimba haina ngura mairi, uye kuramba kwayo ngura kuri nani pane tungsten carbide nealuminium oxide;

Huremu hwakareruka:kuwanda kwe 3.10g/cm3, pedyo nearuminiyamu;

Hapana shanduko:chiyero chidiki kwazvo chekuwedzera kwekupisa,

Inodzivirira kupisa kwakanyanya:zvinhu izvi zvinogona kutsungirira kuchinja kwekushisa nekukurumidza, kuvhunduka kwekupisa, kutonhora nekukurumidza uye kupisa, uye zvine mashandiro akagadzikana.

(2) Zvigadzirwa Zvikuru:

Zvindori zvekusimbisa:Zvigadzirwa zvesilicon carbide zvisina kumanikidzwa zvinowanzoshandiswa kugadzira mhete dzekuvhara dzinoramba kupera uye dzinodzivirira ngura uye mabheyaringi anotsvedza.

Zvikamu zvemakanika:Kusanganisira mabheringi anodziya zvakanyanya, zvisimbiso zvemakanika, maburi, mavharuvhu emhepo, miviri yepombi, zvigadziriso, nezvimwewo.

Zvishandiso zvemakemikari:Inoshandiswa kugadzira mapaipi anodzivirira ngura, matangi ekuchengetera zvinhu, ma reactors nezvisimbiso.

Zvishandiso zvemagetsi:Muindasitiri yemagetsi, silicon carbide isina simba inoshandiswa kugadzira zvinodzivirira kupisa zvakanyanya, zvinhu zvinodziya zvemagetsi uye maswichi ane simba guru.

Midziyo yekicheni:Zvakadai semafuremu ekuvaka ane mutoro, maroller, ma nozzles emurazvo, mapaipi ekutonhodza, nezvimwewo mumakiln ematunnel, makiln emashuttle nedzimwe makiln emaindasitiri.

Mifananidzo Yemashoko

Silicon Carbide Chisimbiso Mhete

Silicon Carbide Pipe

Zvishongo zveSilicon Carbide

Beam reSilicon Carbide

Plate yeSilicon Carbide

Silicon Carbide Grinding Barrel

Index yeChigadzirwa

| Zvigadzirwa zveSSiC | ||

| Chinhu | Chikamu | Mhedzisiro |

| Kuoma | HS | ≥115 |

| Mwero wePorosity | % | <0.2 |

| Kuwanda kwevanhu | g/cm3 | ≥3.10 |

| Simba Rinodzvinyirira | Mpa | ≥2500 |

| Simba Rekukombama | Mpa | ≥380 |

| Kuwanda kweCoefficient | 10-6/℃ | 4.2 |

| Zviri muSiC | % | ≥98 |

| Si Yemahara | % | <1 |

| Modulus yeElastic | Gpa | ≥410 |

| Kupisa Kwakanyanya Kwekushandisa | ℃ | 1400 |

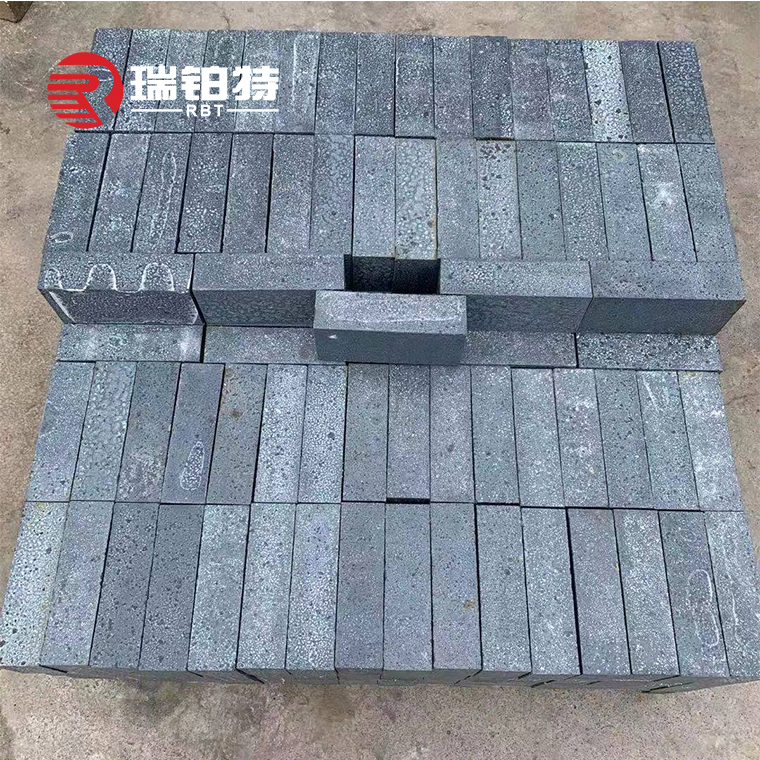

3. Chigadzirwa chesilicon carbide chakagadziriswazve (RSiC Products)

Zvigadzirwa zveSilicon Carbide zvakagadziriswazve chigadzirwa chinorasika chakagadzirwa nesilicon carbide yakachena kwazvo sezvinhu zvakagadziriswa. Chinhu chikuru chayo ndechekuti hapana chikamu chechipiri uye inoumbwa ne100% α-SiC.

(1) Hunhu:

Kuomarara kwakanyanya:Kuoma kwayo kuri pasi pedhaimani chete, uye ine simba guru remakanika uye kuomarara.

Kudzivirira kupisa kwakanyanya:Inogona kuchengetedza kushanda kwakasimba munzvimbo dzinopisa zvakanyanya uye yakakodzera tembiricha ye1350 ~ 1600℃.

Kudzivirira ngura kwakasimba:Inodzivirira ngura zvakanyanya kune zvakasiyana-siyana zvenhau uye inogona kuchengetedzahunhu hwemakanika kwenguva yakareba munzvimbo dzakasiyana-siyana dzinoparadza.

Kudzivirira kwakanaka kwe oxidation:Inodzivirira oxidation zvakanaka uye inogona kushanda zvakanaka pakupisa kwakanyanya.

Kudzivirira kwakanaka kwekupisa:Inoshanda zvakanaka munzvimbo ine shanduko huru dzekupisa uye yakakodzera nzvimbo dzine kupisa kwakanyanya.

Hapana kuderera kwesimba panguva yekupisa:Haiderere panguva yekucheneswa, uye hapana kushushikana kunobva kwasara kuchakonzeresa kuputsika kana kutsemuka kwechigadzirwa. Yakakodzera kugadzirira zvikamu zvine maumbirwo akaomarara uye zvine hungwaru hwakanyanya.

(2) Zvigadzirwa Zvikuru:

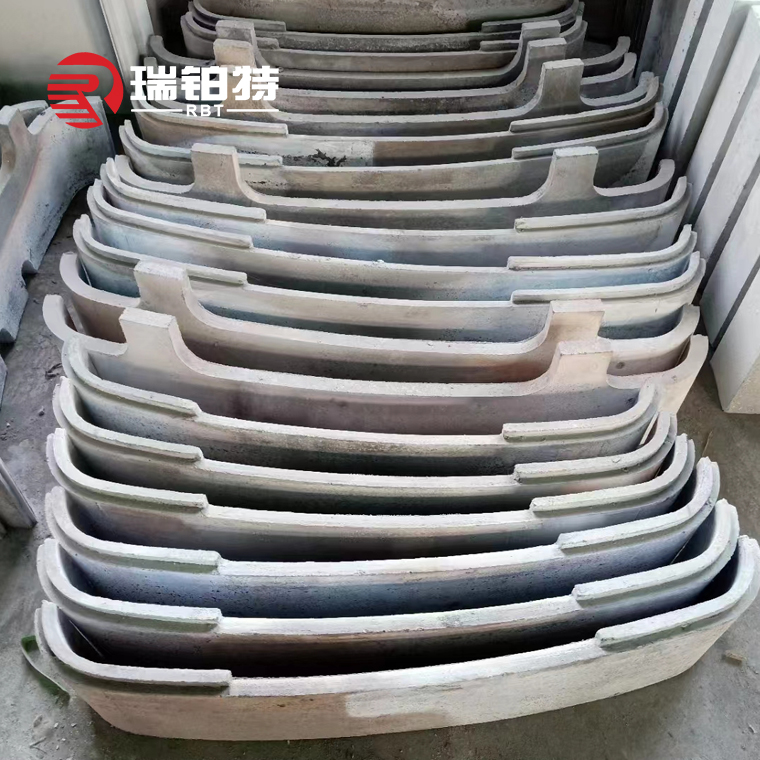

Zvinhu zvekushandisa mukicheni:Inonyanya kushandiswa pakugadzira fenicha yechoto, ine zvakanakira zvekuchengetedza simba, kuwedzera huwandu hunoshanda hwechoto, kupfupisa nguva yekubatidza, kuvandudza kushanda zvakanaka kwechoto uye mabhenefiti ehupfumi.

Maburi emubundu:Inogona kushandiswa semisoro yemuromo wekupisa uye yakakodzera nzvimbo dzinopisa zvakanyanya.

Machubhu ekupisa eCeramic radiation:Machubhu aya ekupisa anoshandisa mukana wekugadzikana kwekupisa kwakanyanya uye kuramba ngura kwesilicon carbide yakadzokororwa uye akakodzera kushandiswa kwakasiyana-siyana mumaindasitiri ekupisa kwakanyanya.

Machubhu ekudzivirira zvikamu:Kunyanya mumaovheni emhepo, zvigadzirwa zvesilicon carbide zvinoshandiswa semachubhu ekudzivirira ane tembiricha yepamusoro uye anodzivirira ngura.

Mapombi ekupisa kwakanyanya, mapombi ekufambisa, mabheyaringi, dzimba dzeinjini:Muminda yemotokari, yendege uye yemauto, zvinhu zvesilicon carbide zvakagadzirwazve zvinogadzirwa kuita mapombi anodziya zvakanyanya, mapombi anopinza, mabheringi uye maenjini, nezvimwewo, zvichishandisa mukana wekudzivirira kupisa kwakanyanya, kuramba ngura neacid nealkali uye kuramba kupfeka.

Mifananidzo Yemashoko

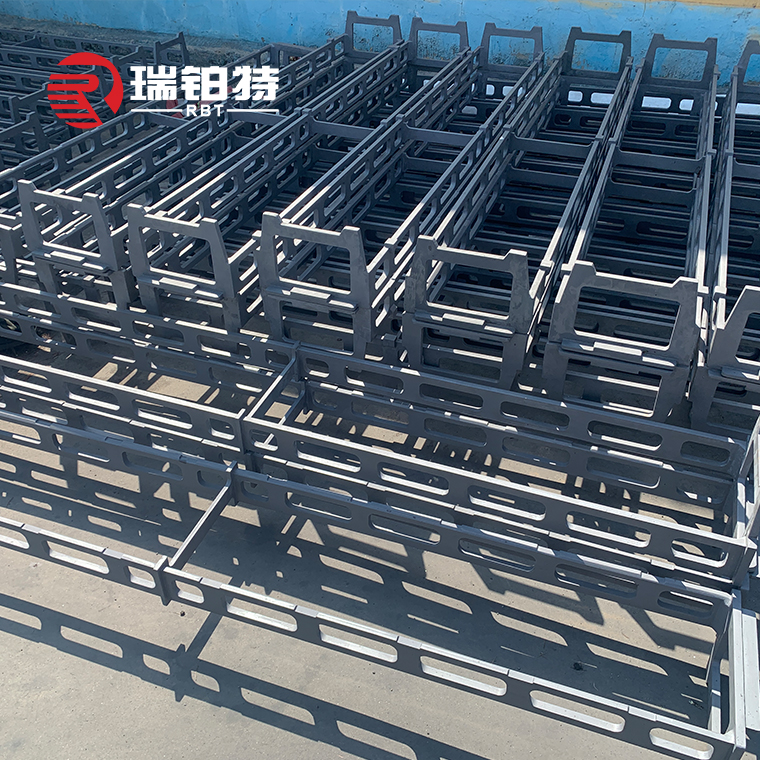

Zvikamu Zvakaumbwa neSilicon Carbide

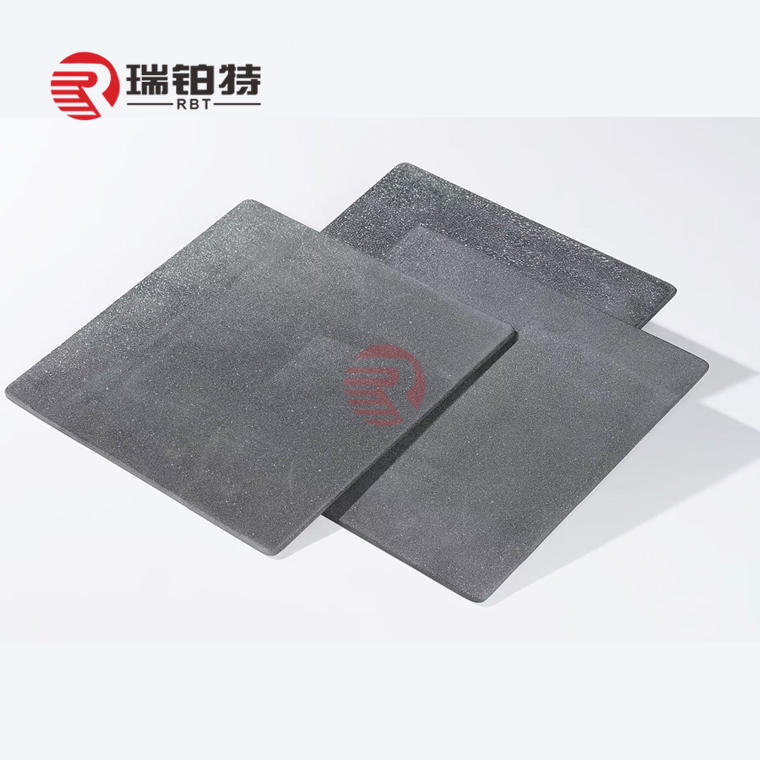

Plate yeSilicon Carbide

Silicon Carbide Roller

Beam reSilicon Carbide

Machubhu ekudzivirira eSilicon Carbide

Midziyo yeKinni

Silicon Carbide Sagger

Chinopfuta nesilicon carbide

Plate yeSilicon Carbide

Silicon Carbide Lgniter

Silicon Carbide Pipe

Silicon Carbide Burner

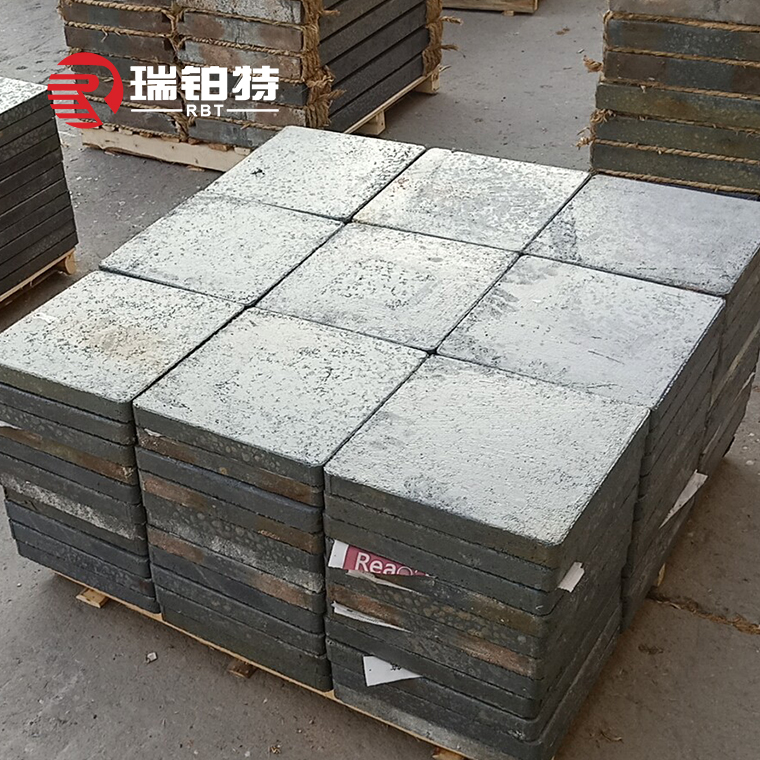

4. Zvigadzirwa zvesilicon carbide zvakasungwa nesilicon nitride (NSiC Products)

Zvigadzirwa zvesilicon carbide zvinosungirirwa nesilicon nitride zvinhu zvakagadzirwa nekuwedzera SiC aggregate ku industrial silicon powder, zvichiita kuti iite nitrogen pakupisa kwakanyanya kuti igadzire Si3N4 uye isanganiswe zvakasimba neSiC particles.

(1) Hunhu:

Kuomarara kwakanyanya:Kuomarara kweMohs kwezvigadzirwa zvesilicon nitride bonded silicon carbide kwakaenzana ne9, kuri kwechipiri kune dhaimani, uye chinhu chine kuomarara kwakanyanya pakati pezvinhu zvisiri zvesimbi.

Simba rekupisa kwakanyanya:Kana tembiricha yakakwira ye1200-1400℃, simba nekuomarara kwechinhu chacho hazvichinji zvachose, uye tembiricha yepamusoro yekushandisa yakachengeteka inogona kusvika 1650-1750℃.

Kugadzikana kwekupisa:Ine thermal expansion coefficient diki uye high thermal conductivity, haisi nyore kugadzira thermal stress, ine thermal shock stability yakanaka uye inodzivirira creep, uye yakakodzera munzvimbo dzinotonhora zvakanyanya uye dzinopisa.

Kugadzikana kwemakemikari:Haipindi ngura uye haipindi okisijeni, uye inogona kuramba yakagadzikana munzvimbo dzakasiyana-siyana dzemakemikari.

Kudzivirira kupfeka:Inodzivirira kupfeka zvakanaka uye yakakodzera kushandiswa mumaindasitiri akasiyana-siyana ane kupfeka kwakanyanya.

(2) Zvigadzirwa Zvikuru:

Zvidhinha zvisingadzoreki:inoshandiswa zvakanyanya mu electrolytic aruminiyamu, maovheni ekuputika kwesimbi, maovheni e arc ari pasi pemvura nedzimwe nzvimbo, ine hunhu hwekudzivirira kupisa kwakanyanya, kuramba ngura, uye kuramba kukurwa kwevhu.

Fenicha yekubikira:inoshandiswa pakugadzira mavhiri ekukuya eceramic, porcelain yemagetsi ine simba guru, makinu emaindasitiri, nezvimwewo, ine simba rakanaka rekutakura mutoro uye inodzivirira kupisa kwakanyanya.

Zvigadzirwa zvine chimiro chakakosha:Inoshandiswa mukugadzira simbi isina ferrous, simba rekupisa, maovheni esimbi akadzika mumvura uye mamwe maindasitiri, ine hunhu hwekudzivirira kupera uye kuramba kupisa kwakanyanya.

Zvikamu zvinoramba zvichichinja:kusanganisira machubhu ekudzivirira thermocouple, machubhu ekukwira, machira ekudziyisa, nezvimwewo, zvinoshandiswa mumaovheni anodziya zvakanyanya uye munzvimbo dzakasiyana-siyana, dzine conductivity yepamusoro yekupisa uye dzinodzivirira ngura.

Mifananidzo Yemashoko

Plate Yakaumbwa neSilicon Carbide

Plate Yakaumbwa neSilicon Carbide

Plate Yakaumbwa neSilicon Carbide

Plate Yakaumbwa neSilicon Carbide

Plate Yakaumbwa neSilicon Carbide

Machubhu eRadiation eSilicon Carbide

Silicon Carbide Pipe

Plate Yakaumbwa neSilicon Carbide

Zvikamu Zvakaumbwa neSilicon Carbide

Machubhu ekudzivirira eSilicon Carbide

Plate yeSilicon Carbide

Zvidhinha zveSilicon Carbide

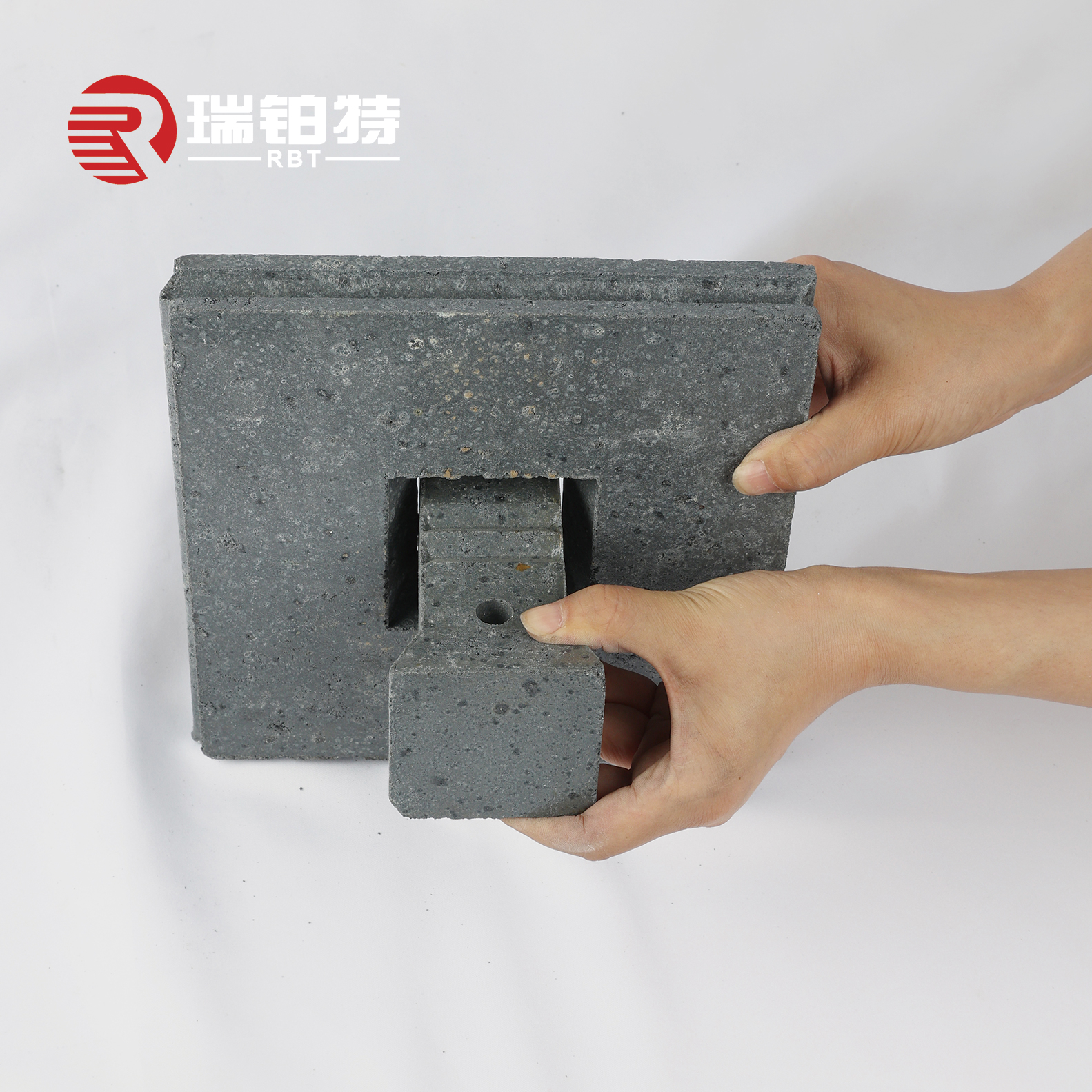

5. Zvigadzirwa zvesilicon carbide zvakasungirirwa neoxide

Zvigadzirwa zvesilicon carbide zvakasungwa neoxide zvinogadzirwa nekusanganisa silicon carbide particles ne oxide powder (senge silicon dioxide kana mullite), kudzvanya nekusvina pakupisa kwakanyanya. Hunhu hwayo ndehwekuti panguva yekusvina nekushandisa, oxide film inoputirwa pa silicon carbide particles, izvo zvinovandudza zvakanyanya kusimba kwe oxidation uye kupisa kwakanyanya.

Ine hunhu hwesimba reflexural rinokwira zvakanyanya pakupisa, kugadzikana kwakanaka kwekupisa, kufambisa kwekupisa kwakanyanya, kuramba kupfeka uye kuramba kwakasimba kukanganiswa nemhepo yakasiyana-siyana, uye chinhu chakanakira kuchengetedza simba remaovheni emaindasitiri.

(2) Zvigadzirwa Zvikuru:

Zvigadzirwa zvesilicon carbide zvakasungwa nesilicon dioxide:Chigadzirwa ichi chinoshandisa silicon dioxide (SiO2) sechikamu chekusunga. Kazhinji 5% ~ 10% yeupfu hwesilicon dioxide kana quartz powder inosanganiswa nesilicon carbide (SiC) particles. Dzimwe nguva flux inowedzerwa. Mushure mekudzvanywa nekuumbwa, inopiswa muchoto chakajairika. Hunhu hwayo ndehwekuti panguva yekupiswa nekushandiswa, firimu resilicon dioxide rinoputirwa pasilicon carbide particles, izvo zvinovandudza zvakanyanya kusimba kweoxidation uye simba rekupisa kwakanyanya. Chigadzirwa ichi chinoshandiswa zvakanyanya mumasherufu echoto ekupisa porcelain (>1300℃), uye hupenyu hwayo hwebasa hunopfuura

zvakapetwa kaviri kupfuura zvigadzirwa zvesilicon carbide zvakasungirirwa nevhu.

Zvigadzirwa zveMullite Bonded silicon carbide:Chigadzirwa ichi chinowedzera hupfu hweα-Al2O3 nehupfu hwesilicon dioxide kune zvinoshandiswa musilicon carbide. Mushure mekudzvanya nekugadzira, Al2O3 neSiO2 zvinosanganiswa kuti zvigadzire mullite panguva yekupiswa. Munguva yekushandiswa, silicon dioxide inoumbwa nekuoxidation yesilicon carbide inoumba mullite neAl2O3. Chinhu ichi chine kugadzikana kwakanaka kwekupisa uye chinoshandiswa zvakanyanya mukugadzira porcelain saggers nemasherufu.

Mifananidzo Yemashoko

Plate yeSilicon Carbide

Zvidhinha zveSilicon Carbide

Plate yeSilicon Carbide

SiC Microcrystalline Pipe

Bhodhi reSiC Microcrystalline

Bhodhi reSiC Microcrystalline

Mbiri Yekambani

Shandong Robert New Material Co., Ltd.iri muZibo City, Shandong Province, China, inova nzvimbo yekugadzira zvinhu zvinoramba kushanda. Isu tiri kambani yemazuva ano inobatanidza tsvakurudzo nekuvandudza, kugadzira, kutengesa, kugadzira nekuvaka zvitofu, tekinoroji, uye kutumira zvinhu zvinoramba kushanda kunze kwenyika. Tine michina yakakwana, tekinoroji yepamusoro, simba rakasimba rehunyanzvi, mhando yepamusoro yechigadzirwa, uye mukurumbira wakanaka. Fekitori yedu inofukidza maeka anopfuura mazana maviri uye gore rega rega zvinhu zvinoramba kushanda zvine chimiro zvinosvika matani zviuru zvitatu uye zvinhu zvisina chimiro zvinosvika matani zviuru gumi nezviviri.

Zvigadzirwa zvedu zvikuru zvezvinhu zvinoramba kusimba zvinosanganisira:zvinhu zvinoramba alkaline; zvinhu zvinoramba aruminiyamu silicon; zvinhu zvisina kuumbwa zvinoramba; zvinhu zvinodzivirira kupisa zvinodzivirira; zvinhu zvakakosha zvinoramba; zvinhu zvinoshanda zvinoramba zvemasisitimu ekukanda anoenderera mberi.

Mibvunzo Inowanzo bvunzwa

Unoda rubatsiro here? Iva nechokwadi chekushanyira maforamu edu ekutsigira kuti uwane mhinduro dzemibvunzo yako!

Isu tiri vagadziri chaivo, fekitari yedu yagara iine hunyanzvi mukugadzira zvinhu zvinoramba kugadzika kweanopfuura makore makumi matatu. Tinovimbisa kupa mutengo wakanakisa, sevhisi yakanakisisa isati yatengeswa uye mushure mekutengesa.

Pakugadzira kwega kwega, RBT ine system yakakwana yeQC yemakemikari uye hunhu hwemuviri. Uye tichaedza zvinhu, uye chitupa chemhando yepamusoro chichatumirwa nezvinhu. Kana muine zvinodiwa zvakakosha, tichaedza nepese patinogona kuti zvienderane nazvo.

Zvichienderana nehuwandu, nguva yedu yekutumira yakasiyana. Asi tinovimbisa kutumira nekukurumidza sezvinobvira nerubatsiro rwemhando.

Ehe, tinopa mienzaniso yemahara.

Ehe, zvechokwadi, munogamuchirwa kushanyira kambani yeRBT nezvigadzirwa zvedu.

Hapana muganho, tinogona kukupa mazano akanakisa uye mhinduro zvichienderana nemamiriro ako ezvinhu.

Tave tichigadzira zvinhu zvinoramba kushanda kwemvura kwemakore anopfuura makumi matatu, tine rutsigiro rwakasimba rwehunyanzvi uye ruzivo rwakakura, tinogona kubatsira vatengi kugadzira makinu akasiyana uye kupa sevhisi imwe chete.