Nhanganyaya

Mumaindasitiri anopisa zvakanyanya—kubva pakugadzira simbi kusvika pakugadzira magirazi—zvinhu zvinonyungudutsa mvura ndizvo zvinonyanya kukosha pakushanda zvakachengeteka uye zvinobudirira. Pakati peizvi,zvidhinha zvemulliteDzinoonekwa nekugadzikana kwadzo kwakanyanya pakupisa, kuramba ngura, uye simba remakanika. Kunzwisisa kupatsanurwa kwadzo uye mashandisirwo adzo kwakakosha kumabhizinesi ari kutsvaga kugadzirisa hupenyu hwemidziyo uye kuderedza mari yekushandisa. Chinyorwa chino chinopa ruzivo nezvemhando dzakakosha dzezvidhinha zvemullite uye mashandisirwo azvo chaiwo, zvichikubatsira kuita sarudzo dzakakodzera zvinodiwa nemaindasitiri.

Kupatsanurwa kweMullite Bricks

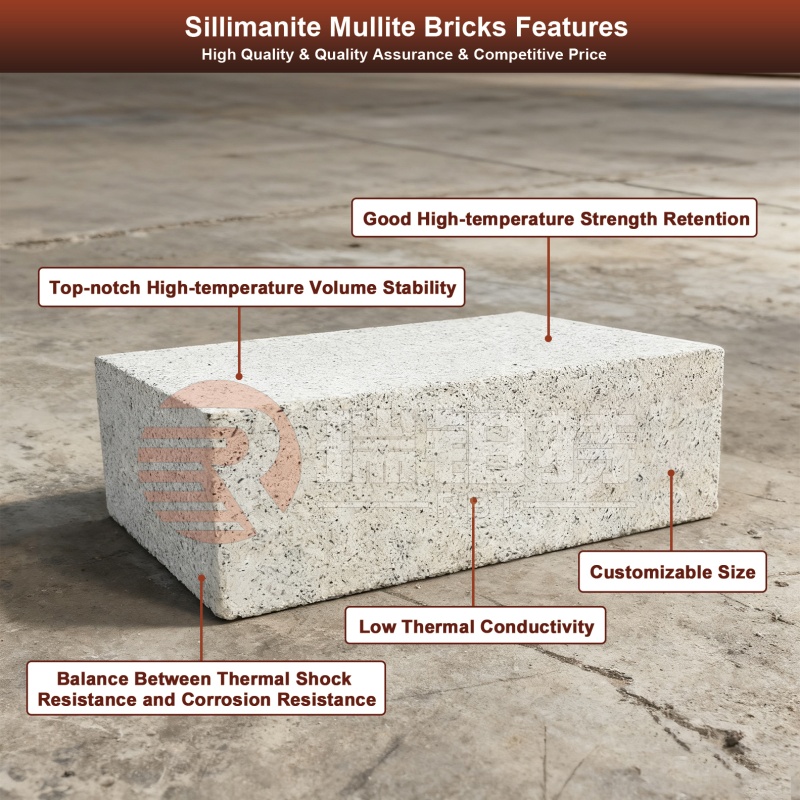

Zvidhinha zveMullite zvinorongwa zvichienderana nemaitiro ekugadzira uye zvimwe zvinhu zvakawedzerwa, chimwe nechimwe chakagadzirirwa zvinodiwa nemaindasitiri chaiwo.

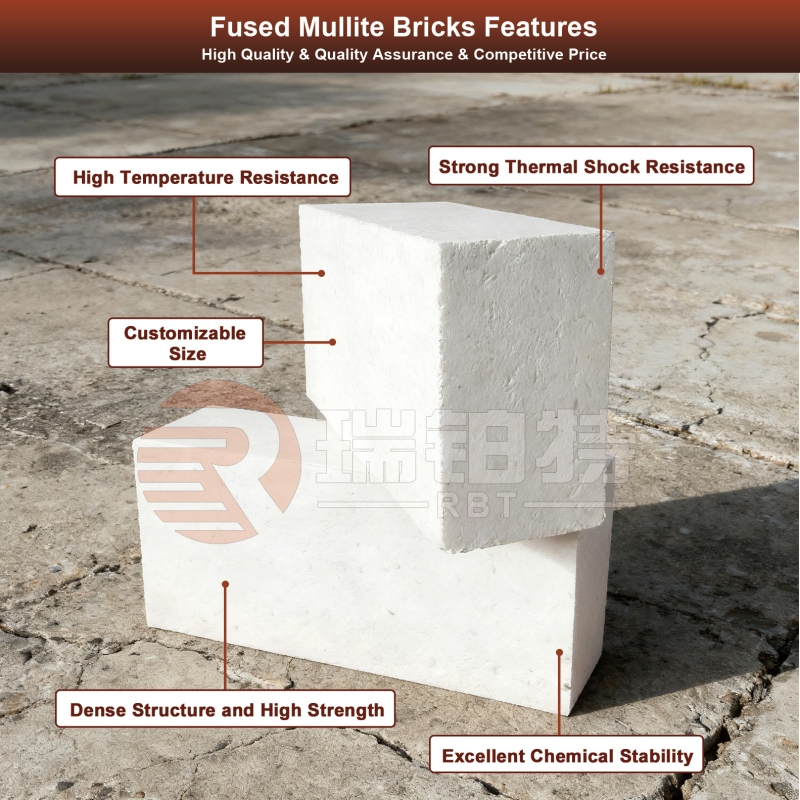

1. Zvidhinha zveMullite Zvakagadzirwa

Zvakagadzirwa nekusanganisa alumina ne silica zvine purity yakakwira, zvichigadzira musanganiswa, uye zvichipiswa patembiricha iri pamusoro pe 1600°C, zvidhinha zve mullite zvakapfava zvine chimiro chakasimba uye porosity yakaderera (kazhinji pasi pe 15%). Hunhu uhwu hunopa simba rakanaka rekudzivirira kupfeka uye kudzivirira kupisa - zvakanakira nzvimbo dzine tembiricha inochinja-chinja. Mashandisirwo akajairika anosanganisira ma linings ema ceramic kilns, blast furnace hot blast stoves, uye boiler combustion chambers.

2. Zvidhinha zveMullite zvakakandwa pamwe chete

Zvigadzirwa nekunyungudutsa zvinhu zvakagadziriswa (alumina, silica) muchoto chemagetsi (chinopfuura 2000°C) uye kukanda musanganiswa wakanyungudutswa muzviumbwa, zvidhinha zvemullite zvakasanganiswa zvine mwero wakaderera wekusvibiswa uye kuchena kwakanyanya kwekristalline. Kudzivirira kwavo kukuru kukurwa kwemakemikari (semuenzaniso, kubva mugirazi rakanyungudutswa kana slags) kunoita kuti zvive sarudzo yepamusoro yezvigadziriso zvegirazi, mabhati egirazi anoyangarara, nezvimwe zvishandiso zvinosangana nemidziyo yakanyungudutswa ine simba.

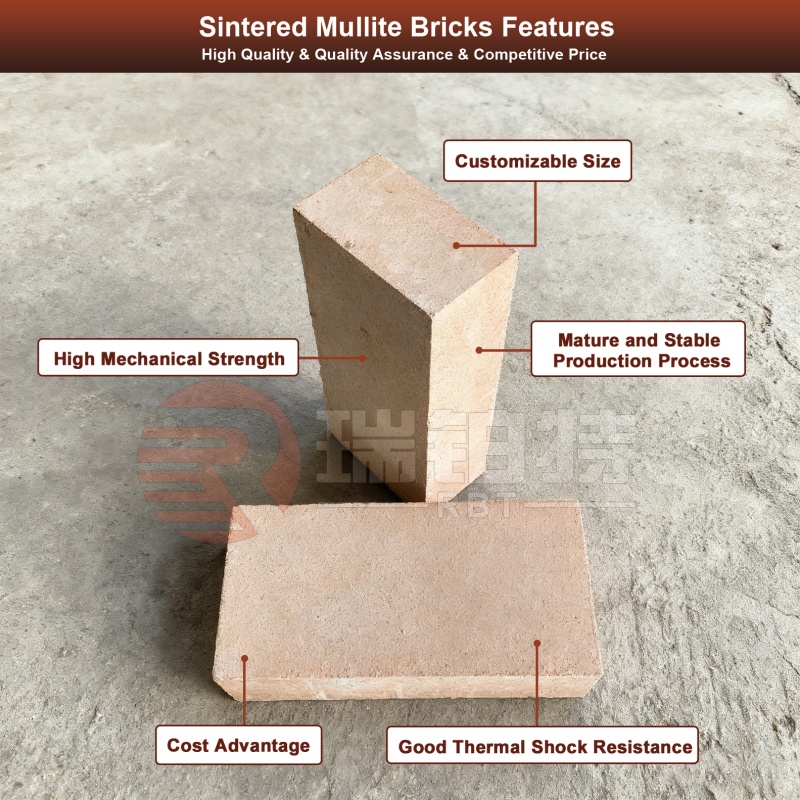

3. Zvidhinha Zvishoma Zvishoma

Zvakagadzirwa nekuwedzera zvinhu zvinogadzira maburi (semuenzaniso, sawdust, graphite) panguva yekugadzira, zvidhinha zvemullite zvidiki zvine maburi e40–60% uye density yakaderera kupfuura mhando dzakasimwa kana dzakasanganiswa. Chinhu chikuru chazvo ndechekuti thermal conductivity yakaderera (0.4–1.2 W/(m·K)), izvo zvinoderedza kurasikirwa nekupisa. Zvinoshandiswa zvakanyanya sezvikamu zvekudzivirira mumakiln, maoven, uye michina yekurapa kupisa, uko huremu nekushanda nesimba zviri zvinhu zvinonyanya kukosheswa.

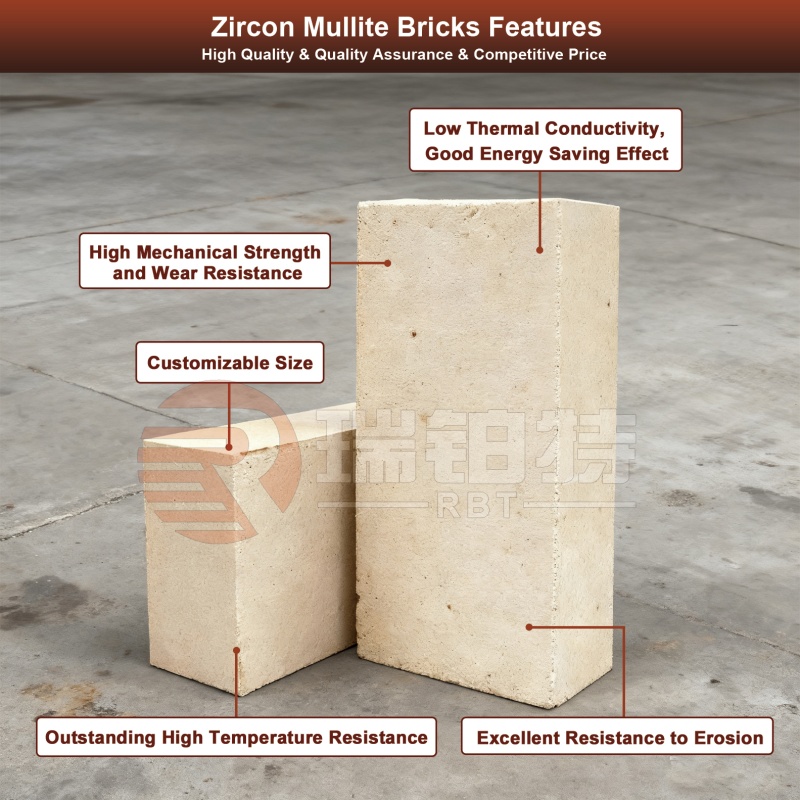

4. Zvidhinha zveZircon Mullite

Nekuisa zircon (ZrSiO₄) mumusanganiswa wezvinhu zvakabikwa, zvidhinha zvezircon mullite zvinowana kushanda kwakanaka pakupisa kwakanyanya—zvinogona kutsungirira tembiricha inosvika 1750°C uye zvinodzivirira kukurwa kweasidhi kubva muacidic slags. Izvi zvinoita kuti zvikodzere nzvimbo dzakaoma dzakadai semafurniture esimbi asina ferrous (semuenzaniso, aluminium reduction cells) uye nzvimbo dzekupisa simende dzinotenderera.

Mashandisirwo eMullite Bricks

Kushandiswa kwezvidhinha zvakawanda kunoita kuti zvive zvakakosha mumaindasitiri akawanda anodziya zvakanyanya.

1. Indasitiri yeSimbi

Kugadzirwa kwesimbi kunosanganisira kupisa kwakanyanya (kusvika 1800°C) uye marara anoparadza. Zvidhinha zvemullite zvakapfava zvinoisa zvitofu zvinopisa, uko kudzivirira kupisa kwadzo kusingapwanyike kubva pakupisa/kutonhodza nekukurumidza. Mhando dzakagadzirwa nesimbi dzakasanganiswa dzinodzivirira madhishi nematundishes, zvichideredza kukurwa kwemarara uye kuwedzera hupenyu hwemidziyo ne20–30% zvichienzaniswa netsika dzekare dzinoramba dzichishandiswa.

2. Indasitiri yeSimende

Makironi anotenderera esimende anoshanda pa1450–1600°C, uye alkaline slags inokonzera njodzi huru yekukukurwa kwevhu. Zvidhinha zveZircon mullite zviri munzvimbo inotsva kironi, zvichidzivirira kurwiswa kwealkali uye zvinochengetedza chimiro chazvo. Zvidhinha zvemullite zvidiki zvinoshandawo sezvikamu zvekudzivirira, zvichideredza kushandiswa kwesimba ne10–15%.

3. Indasitiri yeGirazi

Girazi rakanyungudutswa (1500–1600°C) rinoparadza zvakanyanya, zvichiita kuti zvidhinha zvemullite zvakasanganiswa zvive zvakakosha kune vanogadzirisa girazi muchoto uye matangi. Zvinodzivirira kusvibiswa kwegirazi uye zvinowedzera nguva yekushanda muchoto kusvika makore mashanu kusvika masere, kubva pamakore matatu kusvika mashanu nezvimwe zvinhu.

4. Mamwe Maindasitiri

Mukushongesa simbi isina ferrous (aruminiyamu, mhangura), zvidhinha zvezircon mullite zvinodzivirira simbi yakanyungudutswa uye slag. Mumakemikari epetrochemical, zvidhinha zvemullite zvakachekwa zvinosunga maovheni anotsemuka nekuda kwekugadzikana kwekupisa. Muzvigadzirwa zveceramic, zvidhinha zvemullite zvakareruka zvinodzivirira maovheni, zvichideredza kushandiswa kwesimba.

Mhedziso

Mhando dzakasiyana dzezvidhinha zveMullite—zvakakuyiwa, zvakasanganiswa, zvakareruka, uye zircon—zvinosangana nezvinodiwa nemaindasitiri anodziya zvakanyanya. Kubva pakuwedzera kushanda zvakanaka kwechoto chesimbi kusvika pakuwedzera hupenyu hwechoto chegirazi, zvinopa mabhenefiti anooneka: hupenyu hwemichina hurefu, mitengo yesimba shoma, uye nguva shoma yekushanda. Sezvo maindasitiri achitevera kugadzirwa kwepamusoro uye kuchengetedzeka, zvidhinha zveMullite zvicharamba zviri mhinduro huru. Sarudza mhando yakakodzera yekushandisa kwako, uye vhura kugona kwazvo.

Nguva yekutumira: Gumiguru-31-2025