Tichitora girazi rinoyangarara semuenzaniso, michina mitatu mikuru yekupisa mukugadzirwa kwegirazi inosanganisira furnace inonyungudutsa girazi rinoyangarara, furnace inoyangarara girazi rinoyangarara uye furnace inoyangarara girazi. Mukugadzirwa kwegirazi, furnace inoyangarara girazi ine basa rekunyungudutsa zvinhu zvebatch kuita girazi rinoyangarara uye kujekesa, kuita kuti zvive zvakafanana uye kutonhodza kusvika patembiricha inodiwa pakuumba. Furnace inoyangarara ndiyo michina yakakosha yekuumba girazi. Mvura yegirazi ine tembiricha ye1050 ~ 1100℃ inoyerera kubva mugero rekuyerera ichienda pamusoro pemvura yetin iri mubhavhu retin. Mvura yegirazi inopwanyika uye inokwenenzverwa pamusoro pebhavhu retin, uye inodzorwa nekudhonza kwemashini, maguard emativi uye michina yekudhirowa padivi kuti igadzire ribhoni yegirazi ine upamhi neukobvu hunodiwa. Uye inosiya bhavhu retin painotonhorera zvishoma nezvishoma kusvika 600℃ panguva yekufambisa mberi. Basa refurnace inoyangarara nderekubvisa kushushikana kwakasara uye kusawirirana kwemaziso kwegirazi rinoyangarara, uye kudzikamisa chimiro chemukati chegirazi. Ribhoni yegirazi inoenderera mberi ine tembiricha yeinenge 600℃ inokonzerwa nebhavhu retin inopinda mufurnace inoyangarara kuburikidza netafura inotenderera inotenderera. Midziyo mitatu mikuru iyi yekupisa inoda zvinhu zvinodzivirira kupisa. Kuti ive nechokwadi chekuti girazi rinonyungudutsa rinoita basa rakajairika uye rakagadzikana, hariparadzaniswi nerutsigiro rwezvinhu zvakasiyana-siyana zvinodzivirira kupisa. Inotevera mhando 9 dzezvinhu zvinodzivirira kupisa zvinogara zvichishandiswa mugirazi rinonyungudutsa rinoita basa razvo:

Zvidhinha zvesilica zvemaovheni egirazi:

Zvinhu zvikuru zvinoshandiswa: silicon dioxide (SiO2), huwandu hwayo hunofanirwa kunge huri pamusoro pe94%. Tembiricha yekushanda: tembiricha yepamusoro yekushanda ndeye 1600~1650℃. Zvinhu zviri mairi: haipindi zvakanaka pakukukurwa kweasidhi, asi haipindi zvakanaka pakukukurwa kwezvinhu zvinobhururuka zvine alkaline. Inonyanya kushandiswa pakuvaka maarches makuru, madziro echipfuva uye maovheni madiki.

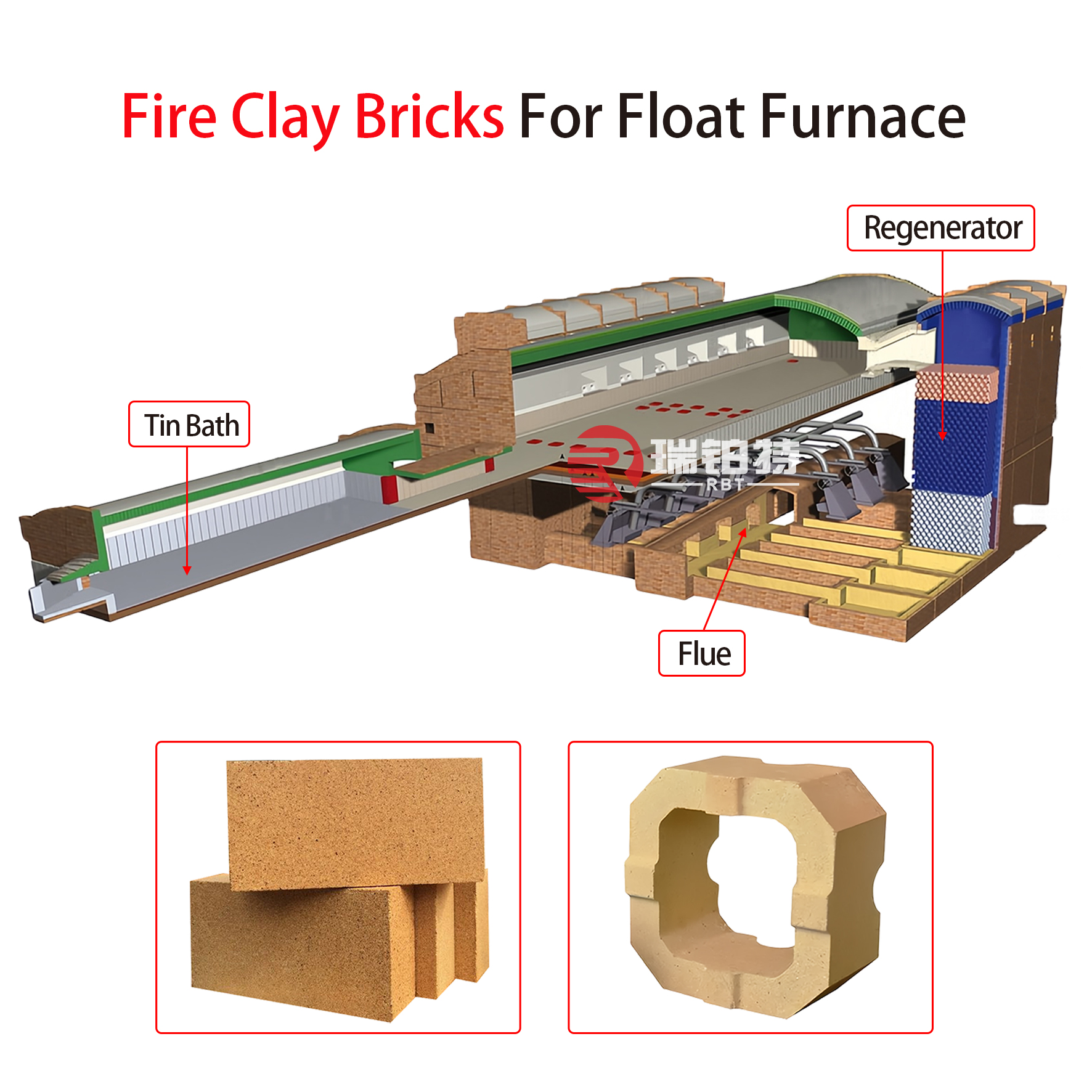

Zvidhinha zvevhu remoto zvemaovheni egirazi:

Zvinhu zvikuru: Al2O3 neSiO2, huwandu hweAl2O3 huri pakati pe30% ~ 45%, SiO2 iri pakati pe51% ~ 66%. Tembiricha yekushandisa: tembiricha yepamusoro yekushandisa ndeye 1350 ~ 1500℃. Zvinhu zviri mairi: Chinhu chisina kusimba asidhi ine simba, ine simba rakanaka rekudzivirira kupisa, uye ine simba shoma rekudzivirira kupisa. Inonyanya kushandiswa pakuvaka pasi pedziva remoto, madziro edziva rechikamu chekushanda uye nzira, madziro, arch, zvidhinha zvechecker zvepasi uye flue yekamuri rekuchengetera kupisa.

Zvidhinha zve alumina zvine aruminiyamu yakawanda zvemaovheni egirazi:

Zvikamu zvikuru: SiO2 neAl2O3, asi huwandu hweAl2O3 hunofanira kupfuura 46%. Tembiricha yekushandisa: Tembiricha yepamusoro yekushandisa ndeye 1500~1650℃. Zvinhu: Inodzivirira ngura zvakanaka, uye inogona kudzivirira ngura kubva muasidhi nealkaline slags. Inonyanya kushandiswa mumakamuri ekuchengetera kupisa, pamwe chete nezvishongedzo zvinodzivirira ngura dzemadziva ekushanda, nzira dzezvinhu uye zvekudyisa.

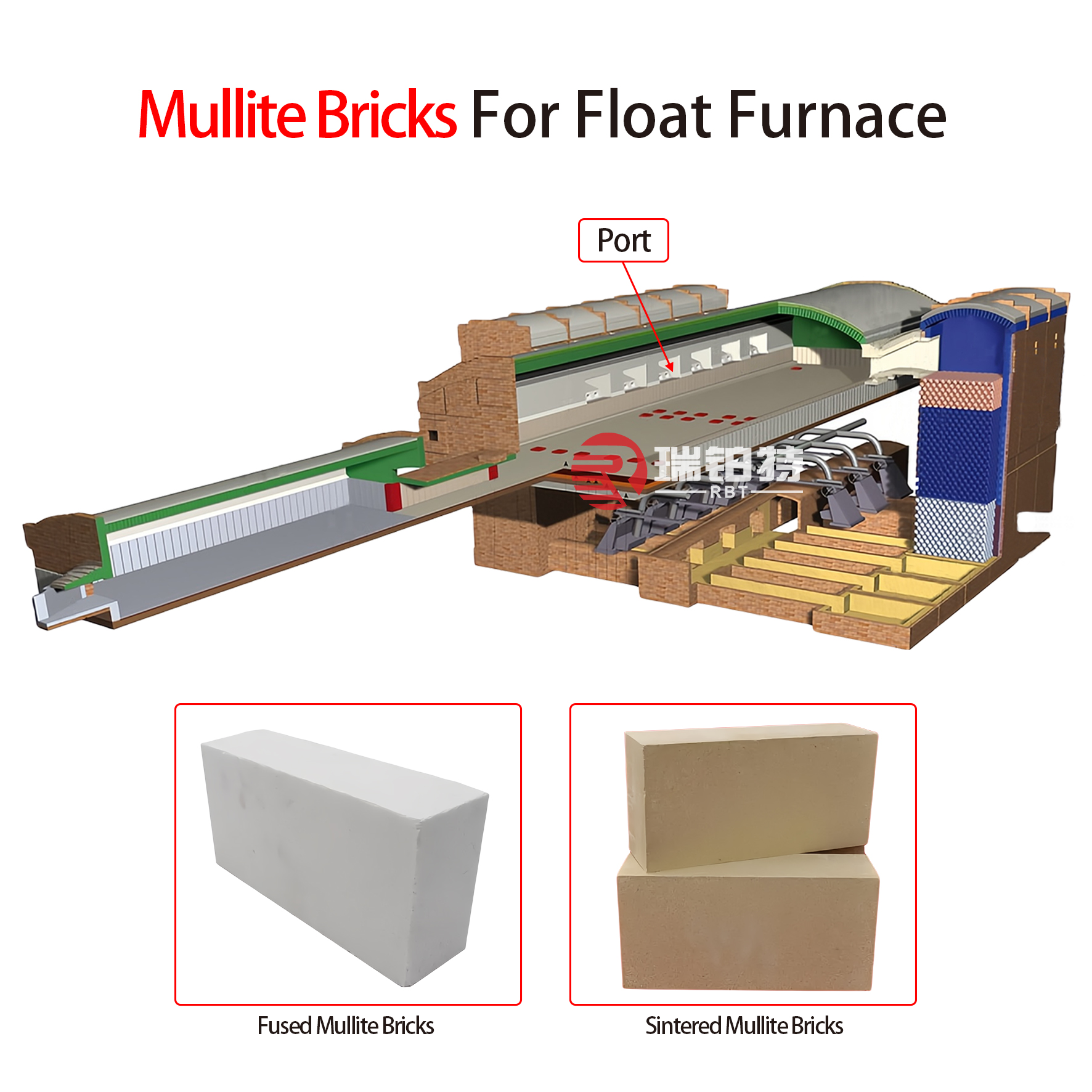

Zvidhinha zvakawanda:

Chinhu chikuru chezvidhinha zvemullite iAl2O3, uye zvirimo zvinosvika 75%. Nekuti zvinonyanya kuve makristaro emullite, zvinonzi zvidhinha zvemullite. Kuwanda kwezvidhinha 2.7-3 2g/cm3, porosity yakavhurika 1%-12%, uye tembiricha yepamusoro yekushanda i1500~1700℃. Mullite yakacheneswa inonyanya kushandiswa pakuvaka madziro ekamuri rekuchengetera kupisa. Mullite yakacheneswa inonyanya kushandiswa pakuvaka madziro edziva, maburi ekutarisa, maburi emadziro, nezvimwewo.

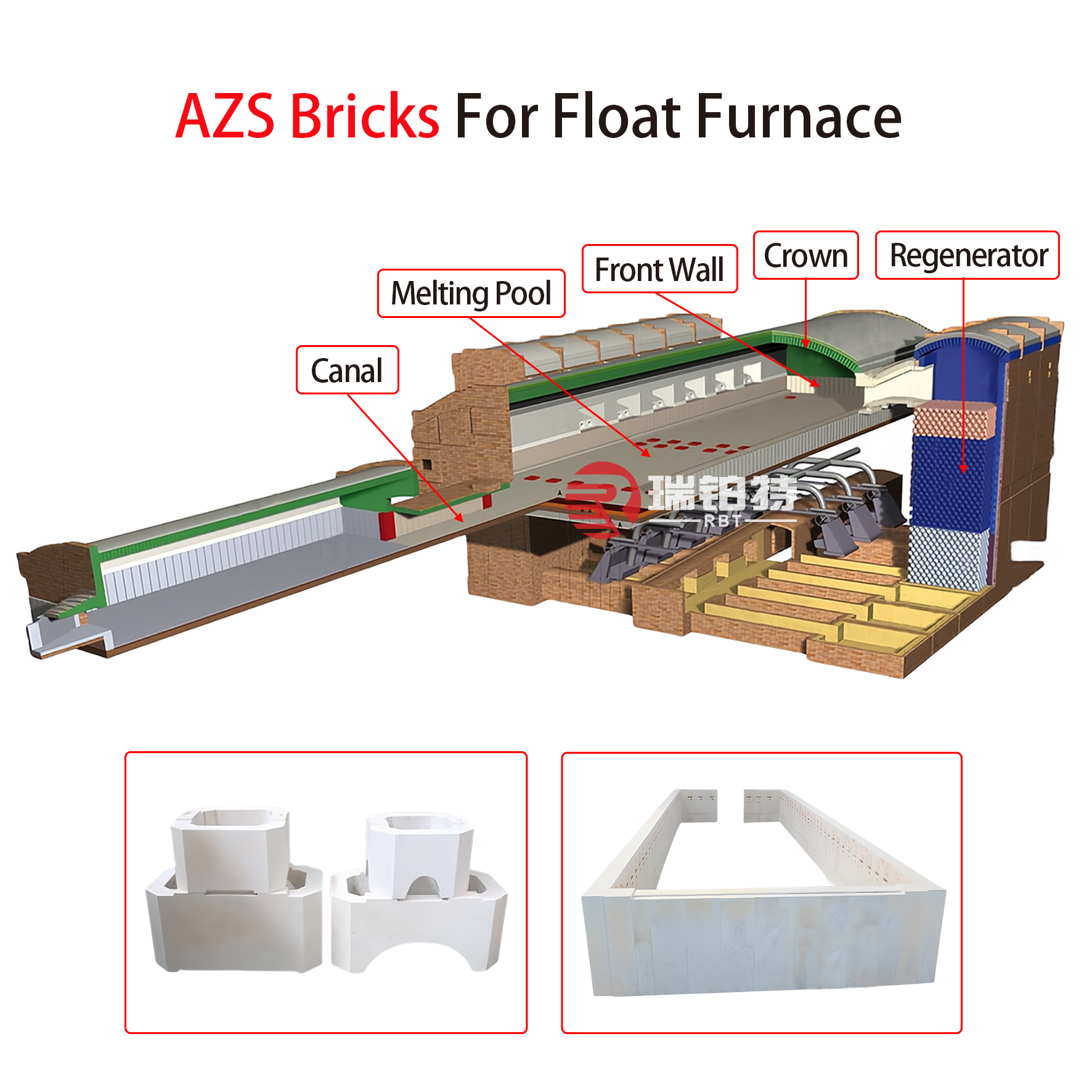

Zvidhinha zve zirconium corundum zvakasanganiswa:

Zvidhinha zvezirconium corundum zvakasanganiswa zvinonziwo zvidhinha zvesimbi chena. Kazhinji, zvidhinha zvezirconium corundum zvakasanganiswa zvakakamurwa kuita zvikamu zvitatu zvichienderana nehuwandu hwezirconium: 33%, 36%, uye 41%. Zvidhinha zvezirconium corundum zvinoshandiswa muindasitiri yegirazi zvine 50% ~ 70% Al2O3 uye 20% ~ 40% ZrO2. Kuwanda kwacho kuri 3.4 ~ 4.0g/cm3, porosity inoonekwa iri 1% ~ 10%, uye tembiricha yepamusoro yekushanda inenge 1700℃. Zvidhinha zvezirconium corundum zvakasanganiswa zvine huwandu hwe33% uye 36% zvinoshandiswa kuvaka madziro edziva remoto, madziro echipfuva ane nzvimbo yemurazvo, maburi madiki emoto, maburi madiki emoto, maburi madiki emoto, maburi madiki emoto, maburi erurimi, nezvimwewo. Zvidhinha zvezirconium corundum zvakasanganiswa zvine huwandu hwe41% zvinoshandiswa kuvaka makona emadziro edziva, maburi ekuyerera, nezvimwe zvikamu apo mvura yegirazi inobvisa nekuparadza zvinhu zvinoramba kupenya zvine simba. Chinhu ichi ndicho chinhu chinonyanya kushandiswa muindasitiri yegirazi.

Zvidhinha zvealumina zvakasanganiswa:

Inonyanya kureva zvidhinha zve α, β corundum, uye β corundum refractory zvakasanganiswa, izvo zvinonyanya kuumbwa ne 92% ~ 94% Al2O3 corundum crystal phase, density 2.9 ~ 3.05g/cm3, appearly porosity 1% ~ 10%, uye kupisa kwakanyanya kwekushanda kweinenge 1700℃. Fused alumina inodzivirira zvakanyanya kupinda kwegirazi uye haina kusvibiswa nemvura yegirazi. Inoshandiswa zvakanyanya mumadziro edziva rekushanda, pasi pedziva, flow channel, working part material channel pool wall, pasi pedziva rematerial channel nezvimwe zvikamu zvegirazi rinonyungudutsa zvinobata mvura yegirazi uye hazvidi kusvibiswa kunopesana negirazi.

Zvidhinha zveQuartz:

Chinhu chikuru iSiO2, ine huwandu hunopfuura 99%, ine density ye1.9~2g/cm3, refractoriness ye1650℃, tembiricha yekushanda inosvika 1600℃, uye inodzivirira kukurwa kweasidhi. Inoshandiswa kuvaka madziro edziva negirazi re acidic boron, zvidhinha zvemaburi emurazvo, nezvimwewo.

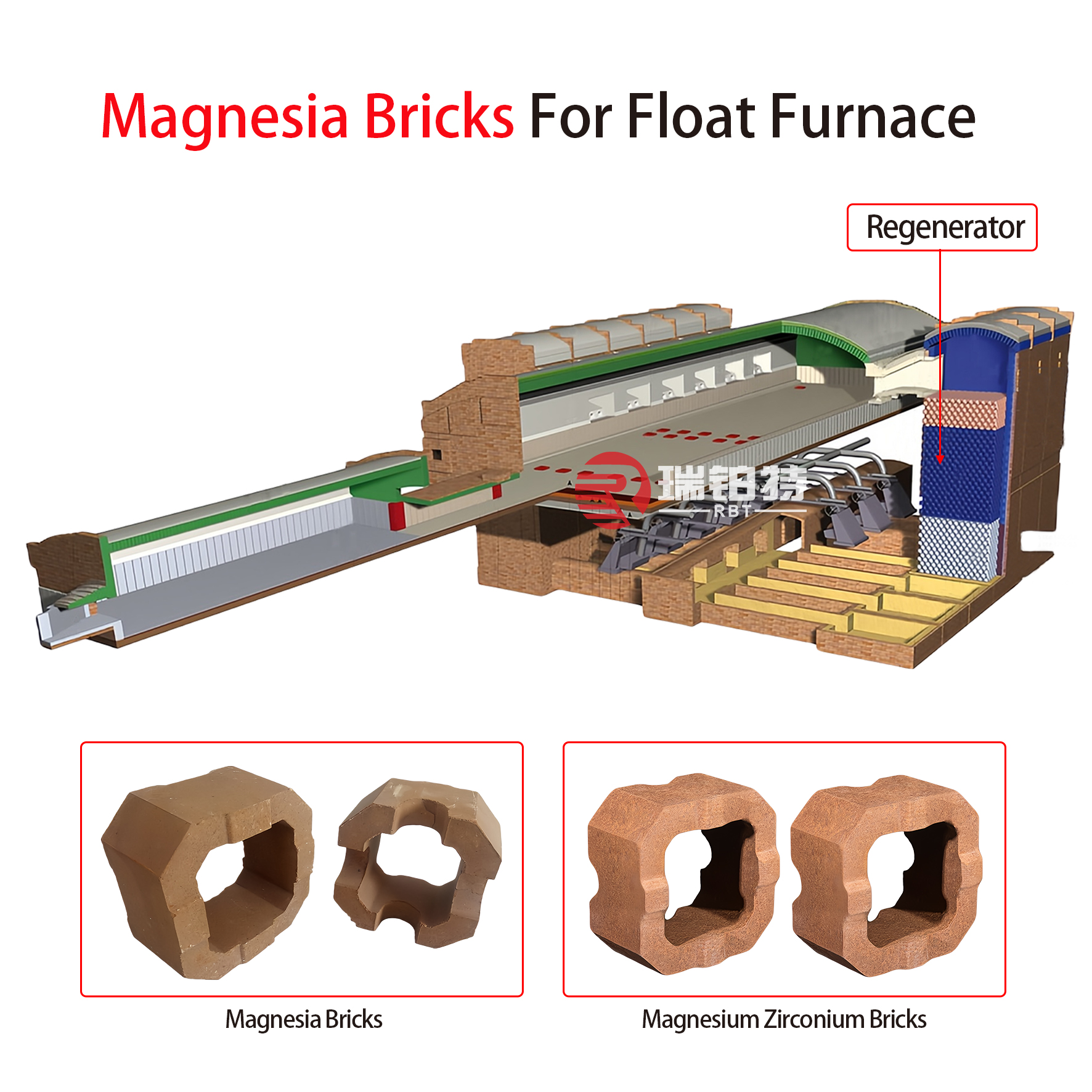

Zvinhu zvinodzivirira alkaline:

Zvinhu zvinodzivirira alkaline zvinonyanya kureva zvidhinha zve magnesia, zvidhinha zve alumina-magnesia, zvidhinha zve magnesia-chrome, uye zvidhinha zve forsterite. Kushanda kwayo kudzivirira kukanganiswa kwezvinhu zvine alkaline, uye kusimba kwayo kuri 1900~2000℃. Inoshandiswa zvakanyanya mumadziro epamusoro e regenerator yegirazi rinonyungudutsa, regenerator arch, grid body, uye chimiro chidiki chechoto.

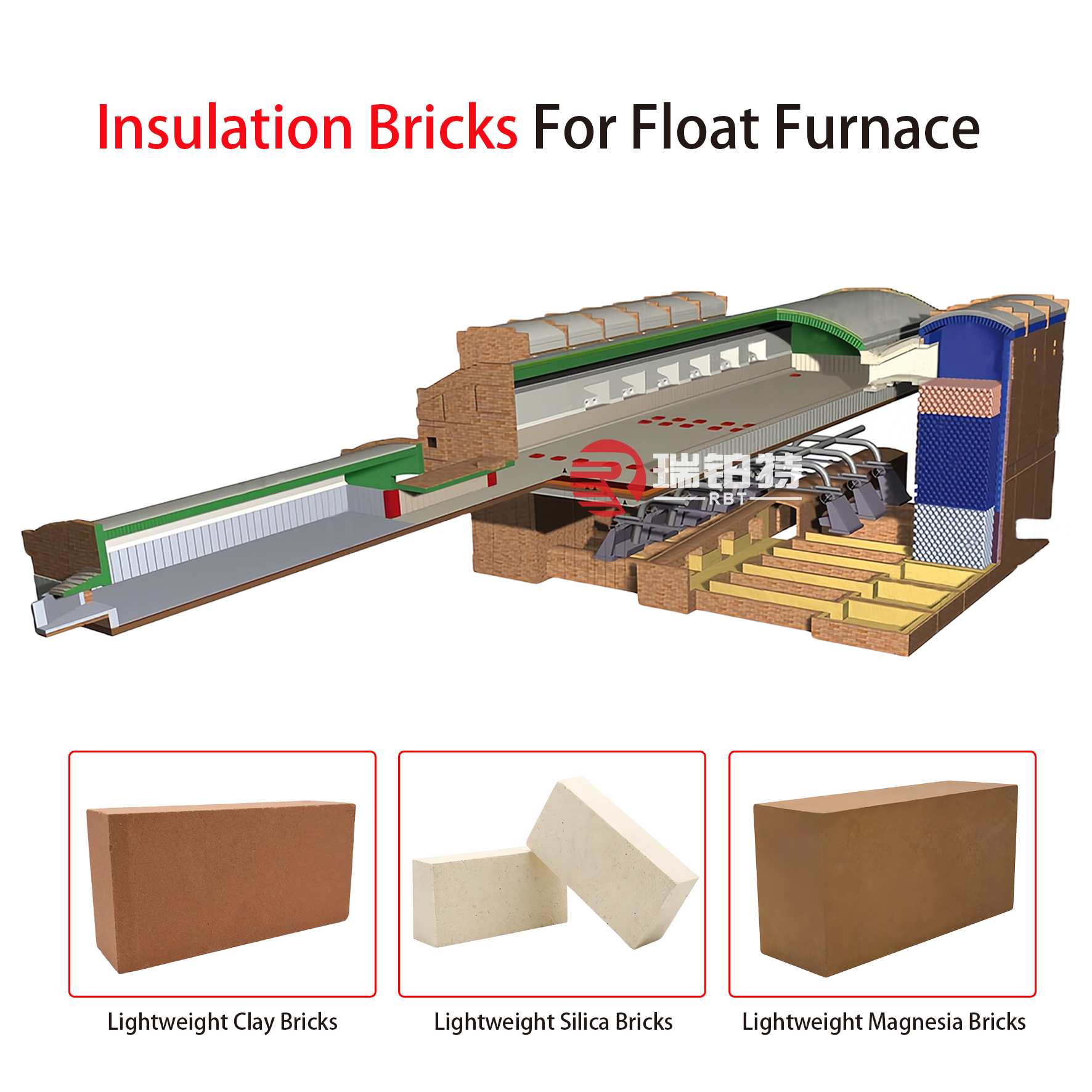

Zvidhinha zvekudzivirira magirazi:

Nzvimbo yekunyungudutsa girazi muchoto chekunyungudutsa girazi yakakura uye kushanda zvakanaka kwekupisa kwakaderera. Kuti tichengetedze simba uye tideredze kushandiswa, zvinhu zvakawanda zvekunyungudutsa zvinodiwa kuti pave nekunyungudutsa kwakazara. Kunyanya, madziro edziva, pasi pedziva, arch, uye madziro ari mu regenerator, chikamu chekunyungudutsa, chikamu chinoshanda, nezvimwewo zvinofanirwa kunyungudutsa kuti zvideredze kupisa. Kurema kwezvidhinha zvekunyungudutsa kwakakura kwazvo, huremu hwacho hwakareruka, uye huwandu hwacho hahupfuure 1.3g/cm3. Sezvo kushanda kwemhepo mukupisa kwakaderera, chidhinha chekunyungudutsa chine porosity yakakura chine insulation effect. Kupisa kwayo kwakaderera ka2 ~ 3 pane kwezvinhu zvinodzora kupisa, saka kana porosity yakakura, insulation effect iri nani. Kune mhando dzakasiyana dzezvidhinha zvekunyungudutsa, zvinosanganisira zvidhinha zvekunyungudutsa zvevhu, zvidhinha zvekunyungudutsa zve silica, zvidhinha zvekunyungudutsa zvine alumina yakawanda nezvimwewo.

Nguva yekutumira: Kubvumbi-25-2025