Lightweight Castable

Product Information

| Product Name | Refractory Castable |

| Categories | Yakaderera simende inokandwa / Yakakwirira simba inokandwa / Yakakwirira alumina inokandwa / Yakareruka inokandwa |

| Composition | Refractory aggregates, powders uye binders |

| Features | 1. Kuvaka nyore 2. Kuramba kwakanaka kwe slag 3. Good corrosion resistance 4. Good fire resistance 5. Kuchengetedza magetsi nekuchengetedzwa kwezvakatipoteredza |

| Products | Low Cement Inokandwa | High Simba Castable |

| Tsanangudzo | Zvigadzirwa zvesimende zvakaderera zvinoreva zvitsva zvinokandwa zvine bhinda resimende shoma.Simende yezvinyorwa zvinokandwa zvinokandwa zvinowanzoita 15% kusvika 20%, uye simende inokandwa pasimendi inokandwa ingangoita 5%, uye mamwe anotoderedzwa kusvika 1% kusvika 2%. | Simba repamusoro rinopfeka-rinodzivirira castable rinoumbwa neyakakura simba aggregate, mineral admixtures, yakakwirira simba aggregate uye anti crack uye kupfeka-resistant agent. |

| Features | Thermal shock resistance, slag resistance, uye kuomarara kwevhu zvinovandudzwa zvakanyanya, kudarika zvidhinha zvakafanana zvinoramba. | Kusimba kwepamusoro, kupfeka kwakakwira kuramba, kupikisa kukanganiswa, kunyura kwevhu, anti-oiri permeability, kudzora chimiro, kusimba kwakasimba, kuvaka kuri nyore, kuita kwakanaka kwekuvaka, uye sevhisi refu. |

| Applications | 1. Lining yemhando dzakasiyana-siyana dzekupisa kupisa, kupisa kwemoto, shaft kilns, rotary kilns, magetsi emoto anovhara, blast furnace tapholes; 2. Self-flowing low-cement castables inokodzera kupisa-kupisa spray gun linings ye spray metallurgy uye petrochemical catalytic cracking reactors Kupfeka-resistant lining, kunze kwekunze kwekupisa choto chekupisa mvura-yakatonhorera pombi, nezvimwewo. | Lining kupfeka-resistant layer ye slag sluice,ore chidyiro, marasha spout, hopper uye silo mune metallurgy, marasha, simba rinopisa, kemikari,simende nemamwe maindasitiri, uye kuputika kwevira kusanganisa silo, sintering silo, feeder, pelletizer, nezvimwe. |

| Products | High Alumina Castable | Lightweight Castable |

| Tsanangudzo | High-aluminium castables ndeye refractorymakanda akagadzirwa nepamusoro-alumina mbishi zvinhuseaggregates uye powders, uye yakawedzerwanemabhainda. | Iyo yakareruka inokandwa ine yakaderera yakawanda density inogadzirwa nealuminate simende, yakakwirira alumina yakanaka zvinhu, ceramsite, uye zvinowedzera. |

| Features | Iine yakakwira mechanical simba uye yakanaka yekupisa kuvhunduka kuramba, abrasion kuramba uye zvimwe zvivakwa. | Yakaderera yakawanda density, diki yekupisa conductivity, yakanaka yekupisa yekupisa mhedzisiro, yakakwira compressive simba, asidhi uye acid gasi corrosion resistance, kupisa kupisa, kupisa kwemafuta, uye kunyura kwemvura. |

| Applications | Inonyanya kushandiswa seyemukati lining yemaboilers, blast furnace inopisa kuputika zvitofu, mavira ekudziya, ceramic kilns nedzimwe honi. | Iyo yakareruka inokandwa inogona kushandiswa kune iyo yekupisa yekuvharisa dhizaini yeakakwira-tembiricha indasitiri yevira uye zvishandiso zvinoshandiswa zvakare kune iyo lining yeyakasiyana-yepamusoro-tembiricha gasi pombi. |

Product Index

| Product Name | Lightweight Castable | ||||||

| Kushanda Limit Temperature | 1100 | 1200 | 1400 | 1500 | 1600 | ||

| 110℃ Bulk Density(g/cm3) ≥ | 1.15 | 1.25 | 1.35 | 1.40 | 1.50 | ||

| Modulus yeKuputika (MPa) ≥ | 110℃×24h | 2.5 | 3 | 3.3 | 3.5 | 3.0 | |

| 1100 ℃ × 3h | 2 | 2 | 2.5 | 3.5 | 3.0 | ||

| 1400℃×3h | ― | ― | 3 | 10.8 | 8.1 | ||

| Cold Crushing Strength(MPa) ≥ | 110℃×24h | 8 | 8 | 11 | 12 | 10 | |

| 1100 ℃ × 3h | 4 | 4 | 5 | 11 | 10 | ||

| 1400℃×3h | ― | ― | 15 | 22 | 14 | ||

| Permanent Linear Shanduko(%) | 1100 ℃ × 3h | -0.65 1000℃×3h | -0.8 | -0.25 | -0.15 | -0.1 | |

| 1400℃×3h | ― | ― | -0.8 | -0.55 | -0.45 | ||

| Thermal Conductivity (W/mk) | 350 ℃ | 0.18 | 0.20 | 0.30 | 0.48 | 0.52 | |

| 700 ℃ | 0.25 | 0.25 | 0.45 | 0.61 | 0.64 | ||

| Al2O3(%) ≥ | 33 | 35 | 45 | 55 | 65 | ||

| Fe2O3(%) ≤ | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 | ||

Application

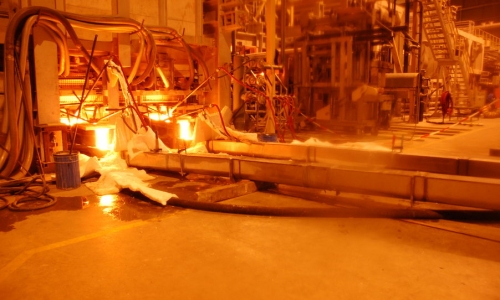

Iron nesimbi indasitiri:Inonyanya kushandiswa kugadzirisa uye kubata kwemagetsi arc furnaces, masimbi ekugadzira simbi, ladles nemimwe michina.

Non-ferrous metal industry:Inoshandiswa pakubata nekugadzirisa mhangura, aruminiyamu, zingi, nickel uye mamwe asiri-ferrous simbi yekunyungudutsa mavira uye anoshandura.

Indasitiri yegirazi:Inoshandiswa kugadzirisa uye chigamba basa regirazi mavira, annealing mavira uye zvimwe zvishandiso.

Indasitiri yezvivakwa zvekuvaka: Inoshandiswa kugadzirisa uye kupeta kwemidziyo yekugadzira yekuvaka senge simende rotary kiln uye gypsum kiln.

Indasitiri yemakemikari:Inoshandiswa kugadzirisa uye kupeta kwepamusoro-tembiricha yemakemikari michina senge catalytic kupaza mavira uye gasifiers.

Ceramic industry:Inoshandiswa kugadzirisa uye kugadzirisa kwemidziyo yekugadzira ceramic senge tunnel kiln uye shuttle kiln.

Package&Warehouse

Mibvunzo Inowanzo bvunzwa

Kuda rubatsiro?Iva nechokwadi chekushanyira maforamu edu ekutsigira mhinduro kumibvunzo yako!

Isu tiri mugadziri chaiye, fekitori yedu inyanzvi mukugadzira zvinhu zvekuramba kweanopfuura makore makumi matatu.Isu tinovimbisa kupa mutengo wakanakisa, yakanakisa pre-kutengesa uye mushure mekutengesa sevhisi.

Kune yega yega maitiro ekugadzira, RBT ine yakazara QC sisitimu yemakemikari ekuumbwa uye emuviri zvivakwa.Uye isu tichaedza zvinhu, uye chitupa chemhando ichaendeswa nenhumbi.Kana iwe uine zvakakosha zvinodiwa, isu tichaedza nepatinogona napo kuti tivape pekugara.

Zvichienderana nehuwandu, nguva yedu yekuendesa yakasiyana.Asi isu tinovimbisa kutumira nekukurumidza sezvinobvira nemhando yakavimbiswa.

Zvechokwadi, tinopa sampuli dzemahara.

Hongu, hongu, unogamuchirwa kushanyira kambani yeRBT uye zvigadzirwa zvedu.

Iko hakuna muganho, isu tinogona kupa yakanakisa zano uye mhinduro zvinoenderana nemamiriro ako.

Tave tichigadzira zvinhu zvekuramba kweanopfuura makore makumi matatu, tine rutsigiro rwakasimba rwehunyanzvi uye ruzivo rwakapfuma, tinokwanisa kubatsira vatengi kugadzira kilns dzakasiyana uye kupa imwe-stop service.