Yakakwirira Alumina Refractory Castable

Product Information

| Product Name | Refractory Castable |

| Categories | Yakaderera Cement Inokandwa/Yakakwirira Simba Inokandwa/Yakakwira Alumina Inokandwa/Yakareruka Inokandwa |

| Composition | Refractory aggregates, powders uye binders |

| Features | 1.Easy Kuvaka, 2.Good Slag Resistance, 3.Good Corrosion Resistance, 4.Good Fire Resistance, 5.Energy Saving And Environmental Protection. |

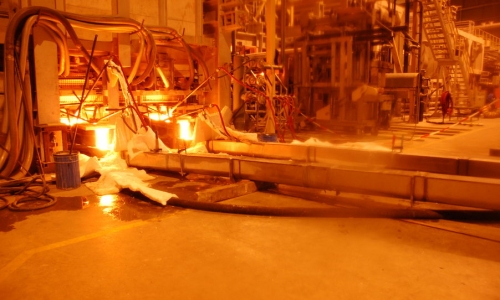

| Applications | Inoshandiswa Zvakawanda Mune Akasiyana Epamusoro Tembiricha Maindasitiri Mafurnaces. |

| Products | Low Cement Inokandwa | High Simba Castable |

| Tsanangudzo | Zvigadzirwa zvesimende zvakaderera zvinoreva zvitsva zvinokandwa zvine bhinda resimende shoma.Simende yezvinyorwa zvinokandwa zvinokandwa zvinowanzoita 15% kusvika 20%, uye simende inokandwa pasimendi inokandwa ingangoita 5%, uye mamwe anotoderedzwa kusvika 1% kusvika 2%. | Simba repamusoro rinopfeka-rinodzivirira castable rinoumbwa neyakakura simba aggregate, mineral admixtures, yakakwirira simba aggregate uye anti crack uye kupfeka-resistant agent. |

| Features | Thermal shock resistance, slag resistance, uye kuomarara kwevhu zvinovandudzwa zvakanyanya, kudarika zvidhinha zvakafanana zvinoramba. | Simba repamusoro, kukwirira kupfeka kuramba, kukanganisa kupikisa, kukura kwevhu, anti-oiri permeability, kutonga kwechimiro, kusimba kwakasimba, kuvaka kuri nyore, kuita kwakanaka kwekuvaka, uye sevhisi refu. |

| Applications | 1.Lining yemhando dzakasiyana-siyana dzekupisa kupisa, kupisa kwemoto, shaft kilns, rotary kilns, magetsi emoto anovhara, blast furnace tapholes; 2.Self-flowing low-cement castables inokodzera kupisa-kupisa spray gun linings for spray metallurgy uye petrochemical catalytic cracking reactors Kupfeka-resistant lining, kunze kwekunze kwekupisa choto chinopisa mvura inotonhorera pombi, nezvimwewo. | Lining kupfeka-resistant layer ye slag sluice,ore chidyiro, marasha spout, hopper uye silo mune metallurgy, marasha, simba rinopisa, kemikari,simende nemamwe maindasitiri, uye kuputika kwevira kusanganisa silo, sintering silo, feeder, pelletizer, nezvimwe. |

| Products | High Alumina Castable | Lightweight Castable |

| Tsanangudzo | High-aluminium castables ndeye refractorymakanda akagadzirwa nepamusoro-alumina mbishi zvinhuseaggregates uye powders, uye yakawedzerwanemabhainda. | Iyo yakareruka inokandwa ine yakaderera yakawanda density inogadzirwa nealuminate simende, yakakwirira alumina yakanaka zvinhu, ceramsite, uye zvinowedzera. |

| Features | Iine yakakwira mechanical simba uye yakanaka yekupisa kuvhunduka kuramba, abrasion kuramba uye zvimwe zvivakwa. | Yakaderera yakawanda density, diki yekupisa conductivity, yakanaka yekupisa yekupisa mhedzisiro, yakakwira compressive simba, asidhi uye acid gasi corrosion resistance, heat insulation, thermal insulation, uye kunyura kwemvura. |

| Applications | Inonyanya kushandiswa seyemukati lining yemaboilers, blast furnace inopisa kuputika zvitofu, mavira ekudziya, ceramic kilns nedzimwe honi. | Iyo yakareruka inokandwa inogona kushandiswa kune yekupisa yekuvharisa musara weyakanyanya-tembiricha indasitiri yevira uye zvishandiso zvinoshandiswa zvakare kune iyo lining yeyakasiyana-yepamusoro-tembiricha gasi pombi. |

Product Index

Hot Blast Stove

Tunnel Kiln

Rotary Kiln

Iron nesimbi indasitiri: inonyanya kushandiswa kugadzirisa uye kupeta kwemagetsi arc furnaces, masimbi ekugadzira simbi, ladles nemimwe michina.

Indasitiri yesimbi isina-ferrous: inoshandiswa kupeta nekugadzirisa mhangura, aruminiyamu, zingi, nickel uye mamwe asina-ferrous simbi yekunyungudutsa mavira uye anoshandura.

Indasitiri yegirazi: inoshandiswa kugadzirisa uye chigamba basa remagirazi evira, annealing mavira uye zvimwe zvishandiso.

| Product Name | Low Cement Inokandwa | |||||

| INDEX | RBTZJ-42 | RBTZJ-60 | RBTZJ-65 | RBTZJS-65 | RBTZJ-70 | |

| Kushanda Limit Temperature | 1300 | 1350 | 1400 | 1400 | 1450 | |

| Bulk Density(g/cm3)110℃×24h ≥ | 2.15 | 2.3 | 2.4 | 2.4 | 2.45 | |

| Cold Bending Strength110℃×24h(MPa) ≥ | 4 | 5 | 6 | 6 | 7 | |

| Cold Crushing Strength(MPa) ≥ | 110℃×24h | 25 | 30 | 35 | 35 | 40 |

| CT℃×3h | 50 1300℃×3h | 55 1350℃×3h | 60 1400℃×3h | 40 1400℃×3h | 70 1400℃×3h | |

| Permanent Linear Shanduko@CT℃×3h(%) | -0.5~+0.5 1300 ℃ | -0.5~+0.5 1350 ℃ | 0~+0.8 1400 ℃ | 0~+0.8 1400 ℃ | 0~+1.0 1400 ℃ | |

| Thermal Shock Resistance (1000 ℃ mvura) ≥ | ― | ― | ― | 20 | ― | |

| Al2O3(%) ≥ | 42 | 60 | 65 | 65 | 70 | |

| CaO(%) ≤ | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 | |

| Fe2O3(%) ≤ | 2.0 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Product Name | High Simba Castable | |||||

| INDEX | HS-50 | HS-60 | HS-70 | HS-80 | HS-90 | |

| Kushanda muganho tembiricha (℃) | 1400 | 1500 | 1600 | 1700 | 1800 | |

| 110℃ Bulk Density(g/cm3) ≥ | 2.15 | 2.30 | 2.40 | 2.50 | 2.90 | |

| Modulus yeKuputika (MPa) ≥ | 110℃×24h | 6 | 8 | 8 | 8.5 | 10 |

| 1100 ℃ × 3h | 8 | 8.5 | 8.5 | 9 | 9.5 | |

| 1400℃×3h | 8.5 1300℃×3h | 9 | 9.5 | 10 | 15 | |

| Cold Crushing Strength(MPa) ≥ | 110℃×24h | 35 | 40 | 40 | 45 | 60 |

| 1100 ℃ × 3h | 40 | 50 | 45 | 50 | 70 | |

| 1400℃×3h | 45 1300℃×3h | 55 | 50 | 55 | 100 | |

| Permanent Linear Shanduko(%) | 1100 ℃ × 3h | -0.2 | -0.2 | -0.25 | -0.15 | -0.1 |

| 1400℃×3h | -0.45 1300℃×3h | -0.4 | -0.3 | -0.3 | -0.1 | |

| Al2O3(%) ≥ | 48 | 48 | 55 | 65 | 75 | 90 |

| CaO(%) ≤ | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 |

| Fe2O3(%) ≤ | 3.5 | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 |

| Product Name | High Alumina Castable | ||||||

| INDEX | Al2O3(%)≥ | CaO(%)≥ | Refractoriness (℃) | CT℃×3h PLC ≤1% | 110℃Mushure mekuomesa (MPa) | ||

| CCS | MOR | ||||||

| Clay Bonded | NL-45 | 45 | ― | 1700 | 1350 | 8 | 1 |

| NL-60 | 60 | ― | 1720 | 1400 | 9 | 1.5 | |

| NL-70 | 70 | ― | 1760 | 1450 | 10 | 2 | |

| Cement Bonded | GL-42 | 42 | ― | 1640 | 1350 | 25 | 3.5 |

| GL-50 | 50 | ― | 1660 | 1400 | 30 | 4 | |

| GL-60 | 60 | ― | 1700 | 1400 | 30 | 4 | |

| GL-70 | 70 | ― | 1720 | 1450 | 35 | 5 | |

| GL-85 | 85 | ― | 1780 | 1500 | 35 | 5 | |

| Low Cement Bonded | DL-60 | 60 | 2.5 | 1740 | 1500 | 30 | 5 |

| DL-80 | 80 | 2.5 | 1780 | 1500 | 40 | 6 | |

| Phosphate Bonded | LL-45 | 45 | ― | 1700 | 1350 | 20 | 3.5 |

| LL-60 | 60 | ― | 1740 | 1450 | 25 | 4 | |

| LL-75 | 75 | ― | 1780 | 1500 | 30 | 5 | |

| Sodium silicate Bonded | BL-40 | 40 | ― | ― | 1000 | 20 | ― |

| Product Name | Lightweight Castable | ||||||

| Kushanda muganhu tembiricha | 1100 | 1200 | 1400 | 1500 | 1600 | ||

| 110℃ Bulk Density(g/cm3) ≥ | 1.15 | 1.25 | 1.35 | 1.40 | 1.50 | ||

| Modulus yeKuputika (MPa) ≥ | 110℃×24h | 2.5 | 3 | 3.3 | 3.5 | 3.0 | |

| 1100 ℃ × 3h | 2 | 2 | 2.5 | 3.5 | 3.0 | ||

| 1400℃×3h | ― | ― | 3 | 10.8 | 8.1 | ||

| Cold Crushing Strength(MPa) ≥ | 110℃×24h | 8 | 8 | 11 | 12 | 10 | |

| 1100 ℃ × 3h | 4 | 4 | 5 | 11 | 10 | ||

| 1400℃×3h | ― | ― | 15 | 22 | 14 | ||

| Permanent Linear Shanduko(%) | 1100 ℃ × 3h | -0.65 1000℃×3h | -0.8 | -0.25 | -0.15 | -0.1 | |

| 1400℃×3h | ― | ― | -0.8 | -0.55 | -0.45 | ||

| Thermal Conductivity (W/mk) | 350 ℃ | 0.18 | 0.20 | 0.30 | 0.48 | 0.52 | |

| 700 ℃ | 0.25 | 0.25 | 0.45 | 0.61 | 0.64 | ||

| Al2O3(%) ≥ | 33 | 35 | 45 | 55 | 65 | ||

| Fe2O3(%) ≤ | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 | ||

Application

Package&Warehouse