Ceramic Foam Filter

Tsananguro yeChigadzirwa

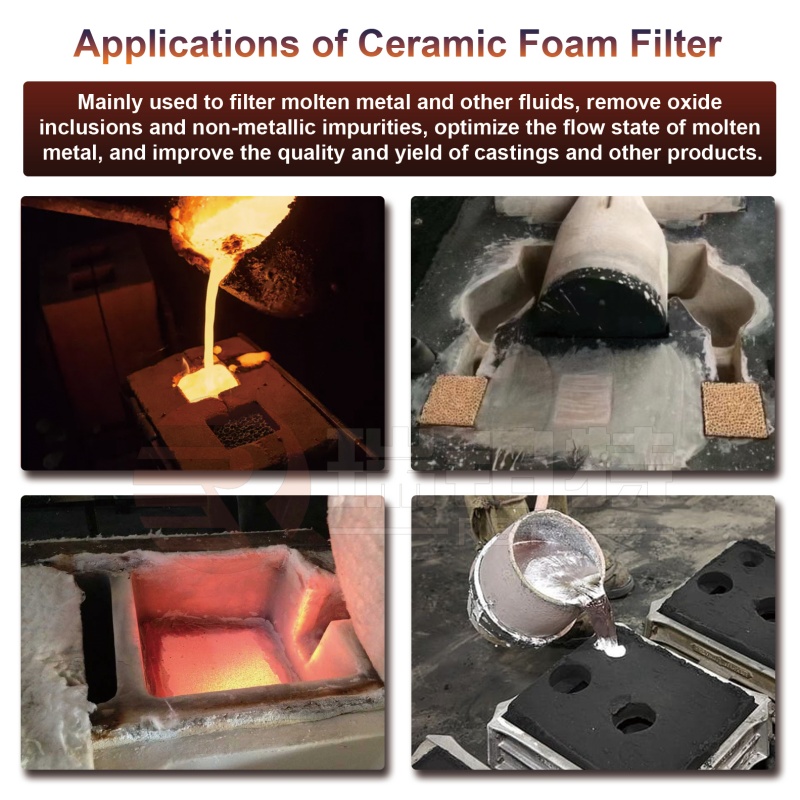

Sefa yefuro reCeramicimhando itsva yezvinhu zvinoshandiswa kusefa mvura dzakadai sesimbi yakanyungudutswa. Ine chimiro chakasiyana uye inoshanda zvakanaka uye inoshandiswa zvakanyanya mumaindasitiri akadai sekukanda.

1. Alumina:

Tembiricha inoshanda: 1250℃. Yakakodzera kusefa nekuchenesa mhinduro dzearuminiyamu ne alloy. Inoshandiswa zvakanyanya mukugadzira jecha uye kugadzira mold zvachose senge kugadzira zvikamu zvearuminiyamu zvemotokari.

Zvakanakira:

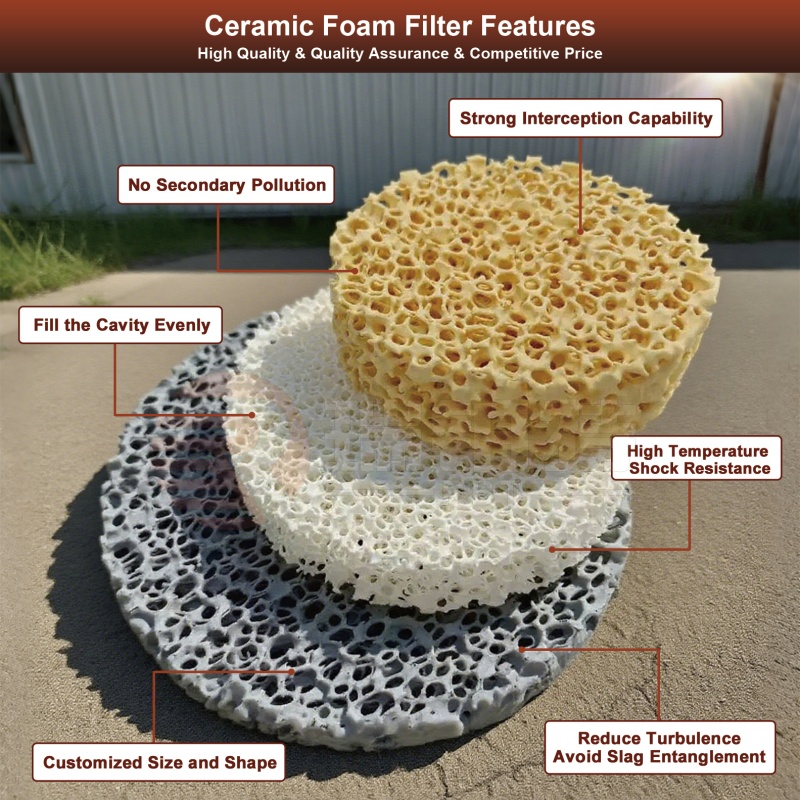

(1) Bvisa tsvina zvinobudirira.

(2) Ruzha rwealuminium rwakanyungudutswa uye rwuri nyore kuzadza.

(3) Deredza kukanganisa kwekukanda, kuvandudza kunaka kwenzvimbo uye hunhu hwechigadzirwa.

2. SIC

Ine simba rakanaka uye inodzivirira kupisa kwakanyanya uye ngura yemakemikari, uye inogona kutsungirira kupisa kwakanyanya kusvika pa1560°C. Yakakodzera kuumba alloys dzemhangura nesimbi yakakandwa.

Zvakanakira:

(1) Bvisa tsvina uye vandudza kuchena kwesimbi yakanyungudutswa zvinobudirira.

(2) Deredza kuvhunduka uye kuzadza kwakaenzana.

(3) Kuvandudza kunaka kwenzvimbo yekukanda uye goho, kuderedza njodzi yekukanganisa.

3. Zirconia

Tembiricha isingapisi zvakanyanya kupfuura 1760℃, ine simba rakawanda uye inodzivirira kupisa zvakanyanya. Inogona kubvisa tsvina mumasimbi anogadzirwa nesimbi uye kugadzirisa kunaka kwepamusoro uye hunhu hwemakanika esimbi.

Zvakanakira:

(1) Deredza tsvina diki.

(2) Deredza kusakwana kwepachiso, vandudza kunaka kwepachiso.

(3) Deredza kukuya, mutengo wekugadzira wakaderera.

4. Kubatana kwakavakirwa pacarbon

Yakagadzirwa zvakananga kushandiswa kwesimbi ine kabhoni nesimbi isina alloy yakawanda, firita yeceramic foam yakagadzirwa nekabhoni yakanakirawo simbi huru dzinoshandiswa pakuumbwa. Inobvisa tsvina yakawanda kubva musimbi yakanyungudutswa ichishandisa nzvimbo yayo yakakura kuti itore zvinhu zvisingaonekwe, zvichiita kuti simbi yakanyungudutswa izare zvakanaka. Izvi zvinoita kuti simbi yakanyungudutswa ive yakachena uye ideredzwe.

kusagadzikana.

Zvakanakira:

(1) Kuwanda kwesimbi kwakaderera, huremu hushoma uye kupisa kwakaderera, zvichikonzera kuchengetwa kwesimbi kwakaderera. Izvi zvinodzivirira simbi yakanyungudutswa kuti isaome mufirita uye zvinoita kuti simbi ipfuure nekukurumidza mufirita. Kuzadzwa kwefirita nekukurumidza kunobatsira kuderedza kuvhunduka kunokonzerwa nekusanganiswa kwesimbi uye slag.

(2) Mhando dzemabasa dzinoshandiswa zvakanyanya, kusanganisira jecha, goko, uye kuumbwa kweceramic kwakanyatsogadzirwa.

(3) Tembiricha yepamusoro yekushandisa ye1650°C, zvichiita kuti zvive nyore zvikuru kushandisa nzira dzekudira dzechinyakare.

(4) Chimiro chesimbi chine mativi matatu chinonyatso gadzirisa kufamba kwesimbi, zvichiita kuti pave nekupararira kwakafanana kwechimiro chesimbi muchikamu chekukanda.

(5) Inosefa tsvina diki isiri yesimbi zvinobudirira, zvichiita kuti zvikamu zvikwanise kushanda zvakanaka.

(6) Inovandudza hunhu hwemakanika hwakakwana hwechigadzirwa, kusanganisira kuomarara kwenzvimbo yacho, simba rekudhonza, kuramba kuneta, uye kureba.

(7) Hapana kukanganisa kwakaipa pakunyunguduka kwechinhu chine firita chakagayiwazve.

Index yeChigadzirwa

| Mamodheru uye maParameter eAlumina Ceramic Foam Filters | |||||

| Chinhu | Simba rekudzvanya (MPa) | Kuyerera kwemvura (%) | Kuwanda kwehuwandu (g/cm3) | Kushanda Tembiricha (≤℃) | Mashandisirwo |

| RBT-01 | ≥0.8 | 80-90 | 0.35-0.55 | 1200 | Kukanda Aruminiyamu Chiwanikwa |

| RBT-01B | ≥0.4 | 80-90 | 0.35-0.55 | 1200 | Kukanda Aruminiyamu Yakakura |

| Kukura uye Kugona kweAlumina Ceramic Foam Filters | ||||

| Saizi(mm) | Kurema (kg) | Mwero wekuyerera (kg/s) | Kurema (kg) | Mwero wekuyerera (kg/s) |

| 10ppi | 20ppi | |||

| 50*50*22 | 42 | 2 | 30 | 1.5 |

| 75*75*22 | 96 | 5 | 67 | 4 |

| 100*100*22 | 170 | 9 | 120 | 7 |

| φ50*22 | 33 | 1.5 | 24 | 1.5 |

| φ75*22 | 75 | 4 | 53 | 3 |

| φ90*22 | 107 | 5 | 77 | 4.5 |

| Saizi Yakakura (Inch) | Kurema (Tani) 20,30,40ppi | Mwero wekuyerera (kg/min) | ||

| 7"*7"*2" | 4.2 | 25-50 | ||

| 9"*9"*2" | 6 | 25-75 | ||

| 10"*10"*2" | 6.9 | 45-100 | ||

| 12"*12"*2" | 13.5 | 90-170 | ||

| 15"*15"*2" | 23.2 | 130-280 | ||

| 17"*17"*2" | 34.5 | 180-370 | ||

| 20"*20"*2" | 43.7 | 270-520 | ||

| 30"*23"*2" | 57.3 | 360-700 | ||

| Mamodheru uye maParameter eSIC Ceramic Foam Filters | |||||

| Chinhu | Simba rekudzvanya (MPa) | Kuyerera kwemvura (%) | Kuwanda kwehuwandu (g/cm3) | Kushanda Tembiricha (≤℃) | Mashandisirwo |

| RBT-0201 | ≥1.2 | ≥80 | 0.40-0.55 | 1480 | Ductile iron, grey iron uye non-ferro alloy |

| RBT-0202 | ≥1.5 | ≥80 | 0.35-0.60 | 1500 | Yekupinza zvakananga uye kukanda simbi hombe |

| RBT-0203 | ≥1.8 | ≥80 | 0.47-0.55 | 1480 | Yekushandisa turbine yemhepo uye ma "castings" makuru |

| Kukura uye Kugona kweSIC Ceramic Foam Filters | ||||||||

| Saizi(mm) | 10ppi | 20ppi | ||||||

| Kurema (kg) | Mwero wekuyerera (kg/s) | Kurema (kg) | Mwero wekuyerera (kg/s) | |||||

| Gireyi Simbi | Ductile Simbi | Simbi yeGrey | Ductile Simbi | Simbi yeGrey | Ductile Simbi | Simbi yeGrey | Ductile Simbi | |

| 40*40*15 | 40 | 22 | 3.1 | 2.3 | 35 | 18 | 2.9 | 2.2 |

| 40*40*22 | 64 | 32 | 4 | 3 | 50 | 25 | 3.2 | 2.5 |

| 50*30*22 | 60 | 30 | 4 | 3 | 48 | 24 | 3.5 | 2.5 |

| 50*50*15 | 50 | 30 | 3.5 | 2.6 | 45 | 26 | 3.2 | 2.5 |

| 50*50*22 | 100 | 50 | 6 | 4 | 80 | 40 | 5 | 3 |

| 75*50*22 | 150 | 75 | 9 | 6 | 120 | 60 | 7 | 5 |

| 75*75*22 | 220 | 110 | 14 | 9 | 176 | 88 | 11 | 7 |

| 100*50*22 | 200 | 100 | 12 | 8 | 160 | 80 | 10 | 6.5 |

| 100*100*22 | 400 | 200 | 24 | 15 | 320 | 160 | 19 | 12 |

| 150*150*22 | 900 | 450 | 50 | 36 | 720 | 360 | 40 | 30 |

| 150*150*40 | 850-1000 | 650-850 | 52-65 | 54-70 | _ | _ | _ | _ |

| 300*150*40 | 1200-1500 | 1000-1300 | 75-95 | 77-100 | _ | _ | _ | _ |

| φ50*22 | 80 | 40 | 5 | 4 | 64 | 32 | 4 | 3.2 |

| φ60*22 | 110 | 55 | 6 | 5 | 88 | 44 | 4.8 | 4 |

| φ75*22 | 176 | 88 | 11 | 7 | 140 | 70 | 8.8 | 5.6 |

| φ80*22 | 200 | 100 | 12 | 8 | 160 | 80 | 9.6 | 6.4 |

| φ90*22 | 240 | 120 | 16 | 10 | 190 | 96 | 9.6 | 8 |

| φ100*22 | 314 | 157 | 19 | 12 | 252 | 126 | 15.2 | 9.6 |

| φ125*25 | 400 | 220 | 28 | 18 | 320 | 176 | 22.4 | 14.4 |

| MaModheru neParameters eZirconia Ceramic Foam Filters | |||||

| Chinhu | Simba rekudzvanya (MPa) | Kuyerera kwemvura (%) | Kuwanda kwehuwandu (g/cm3) | Kushanda Tembiricha (≤℃) | Mashandisirwo |

| RBT-03 | ≥2.0 | ≥80 | 0.75-1.00 | 1700 | Yesimbi isina ngura, simbi yeCarbon uye simbi yakakura yekukanda simbi |

| Kukura uye Kugona kweZirconia Ceramic Foam Filters | |||

| Saizi(mm) | Mwero wekuyerera (kg/s) | Kugona (kg) | |

| Simbi yeKabhoni | Simbi Yakasanganiswa | ||

| 50*50*22 | 2 | 3 | 55 |

| 50*50*25 | 2 | 3 | 55 |

| 55*55*25 | 4 | 5 | 75 |

| 60*60*22 | 3 | 4 | 80 |

| 60*60*25 | 4.5 | 5.5 | 86 |

| 66*66*22 | 3.5 | 5 | 97 |

| 75*75*25 | 4.5 | 7 | 120 |

| 100*100*25 | 8 | 10.5 | 220 |

| 125*125*30 | 18 | 20 | 375 |

| 150*150*30 | 18 | 23 | 490 |

| 200*200*35 | 48 | 53 | 960 |

| φ50*22 | 1.5 | 2.5 | 50 |

| φ50*25 | 1.5 | 2.5 | 50 |

| φ60*22 | 2 | 3.5 | 70 |

| φ60*25 | 2 | 3.5 | 70 |

| φ70*25 | 3 | 4.5 | 90 |

| φ75*25 | 3.5 | 5.5 | 110 |

| φ90*25 | 5 | 7.5 | 150 |

| φ100*25 | 6.5 | 9.5 | 180 |

| φ125*30 | 10 | 13 | 280 |

| φ150*30 | 13 | 17 | 400 |

| φ200*35 | 26 | 33 | 720 |

| Mamodheru uye maParameter eCarbon-based Bonding Ceramic Foam Filters | |||||

| Chinhu | Simba rekudzvanya (MPa) | Kuyerera kwemvura (%) | Kuwanda kwehuwandu (g/cm3) | Kushanda Tembiricha (≤℃) | Mashandisirwo |

| RBT-Kabhoni | ≥1.0 | ≥76 | 0.4-0.55 | 1650 | Simbi yekabhoni, simbi isina alloy yakawanda, simbi hombe dzakagadzirwa. |

| Saizi yeMafirita eCeramic Foam ane Carbon-based Bonding | |

| 50*50*22 10/20ppi | φ50*22 10/20ppi |

| 55*55*25 10/20ppi | φ50*25 10/20ppi |

| 75*75*22 10/20ppi | φ60*25 10/20ppi |

| 75*75*25 10/20ppi | φ70*25 10/20ppi |

| 80*80*25 10/20ppi | φ75*25 10/20ppi |

| 90*90*25 10/20ppi | φ80*25 10/20ppi |

| 100*100*25 10/20ppi | φ90*25 10/20ppi |

| 125*125*30 10/20ppi | φ100*25 10/20ppi |

| 150*150*30 10/20ppi | φ125*30 10/20ppi |

| 175*175*30 10/20ppi | φ150*30 10/20ppi |

| 200*200*35 10/20ppi | φ200*35 10/20ppi |

| 250*250*35 10/20ppi | φ250*35 10/20ppi |

Mbiri Yekambani

Shandong Robert New Material Co., Ltd.iri muZibo City, Shandong Province, China, inova nzvimbo yekugadzira zvinhu zvinoramba kushanda. Isu tiri kambani yemazuva ano inobatanidza tsvakurudzo nekuvandudza, kugadzira, kutengesa, dhizaini yekubikira nekuvaka, tekinoroji, uye kutumira zvinhu zvinoramba kushanda kunze kwenyika. Tine michina yakakwana, tekinoroji yepamusoro, simba rakasimba rehunyanzvi, mhando yepamusoro yechigadzirwa, uye mukurumbira wakanaka. Fekitori yedu inofukidza maeka anopfuura mazana maviri uye gore rega rega zvinhu zvinoramba kushanda zvine chimiro zvinosvika matani zviuru zvitatu uye zvinhu zvisina chimiro zvinosvika matani zviuru gumi nezviviri.

Zvigadzirwa zvedu zvikuru zvezvinhu zvinoramba kusimba zvinosanganisira:zvinhu zvinoramba alkaline; zvinhu zvinoramba aruminiyamu silicon; zvinhu zvisina kuumbwa zvinoramba; zvinhu zvinodzivirira kupisa zvinodzivirira; zvinhu zvakakosha zvinoramba; zvinhu zvinoshanda zvinoramba zvemasisitimu ekukanda anoenderera mberi.

Mibvunzo Inowanzo bvunzwa

Unoda rubatsiro here? Iva nechokwadi chekushanyira maforamu edu ekutsigira kuti uwane mhinduro dzemibvunzo yako!

Isu tiri vagadziri chaivo, fekitari yedu yagara iine hunyanzvi mukugadzira zvinhu zvinoramba kugadzika kweanopfuura makore makumi matatu. Tinovimbisa kupa mutengo wakanakisa, sevhisi yakanakisisa isati yatengeswa uye mushure mekutengesa.

Pakugadzira kwega kwega, RBT ine QC system yakakwana yemakemikari uye hunhu hwemuviri. Uye tichaedza zvinhu, uye chitupa chemhando yepamusoro chichatumirwa nezvinhu. Kana muine zvinodiwa zvakakosha, tichaedza nepese patinogona kuti zvienderane nazvo.

Zvichienderana nehuwandu, nguva yedu yekutumira yakasiyana. Asi tinovimbisa kutumira nekukurumidza sezvinobvira nerubatsiro rwemhando.

Ehe, tinopa mienzaniso yemahara.

Ehe, zvechokwadi, munogamuchirwa kushanyira kambani yeRBT nezvigadzirwa zvedu.

Hapana muganho, tinogona kukupa mazano akanakisa uye mhinduro zvichienderana nemamiriro ako ezvinhu.

Tave tichigadzira zvinhu zvinoramba kushanda kwemvura kwemakore anopfuura makumi matatu, tine rutsigiro rwakasimba rwehunyanzvi uye ruzivo rwakakura, tinogona kubatsira vatengi kugadzira makinu akasiyana uye kupa sevhisi imwe chete.